Development trend of silicone sealants

2025-05-30

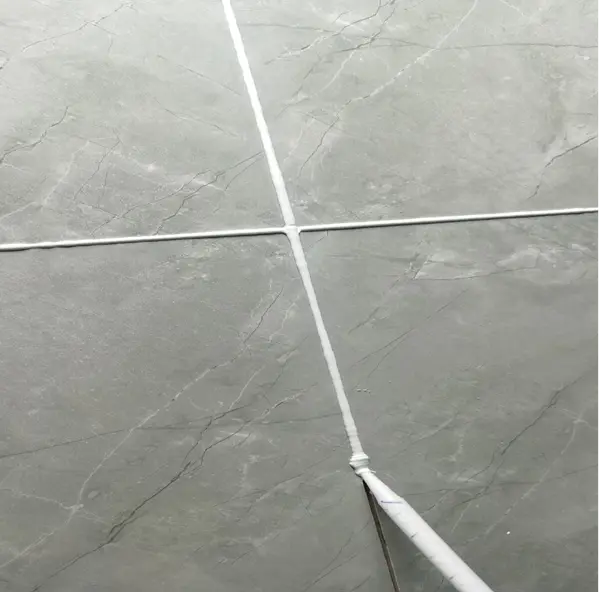

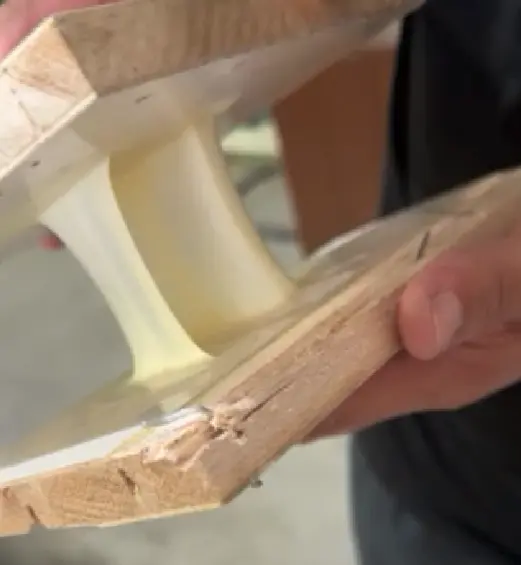

In 2025, we see many developments in material technology, construction and manufacturing, especially Silicone Sealants. Silicone sealants are a versatile material that can be used to create long-lasting and durable seals in applications including, but not limited to, construction, automotive and electronics. This blog will provide an in-depth comparative analysis of modern silicone sealant technology, focusing on its formulations, performance characteristics and innovations in the production process. These trends are important for manufacturers and builders alike

Shandong Bond New Materials Co., Ltd., located in Linyi, Shandong Province, China, focuses on the research and development of adhesive products, of which silicone sealants account for a major share. Bond is committed to excellence and innovation, always keeping up with the changing market needs to ensure that its products remain competitive. As we embark on the forefront of the latest knowledge about silicone sealant technology, we hope to convey meaningful insights on performance retention talents, environmental considerations and emerging trends

Looking ahead, silicone sealant technology has a bright future and its application areas will undergo significant changes. Trends show that people are strongly favoring environmentally friendly formulations that not only meet performance specifications but also take environmental considerations into account. Manufacturers are widely choosing bio-based silicones derived from renewable resources, which are expected to have a low carbon footprint and contribute to sustainable construction, as this trend reflects the growing trend of industries to integrate sustainability into their core business. In addition to this, the advancement of modern technology has also paved the way for higher performance of silicone sealants.

Innovations in modern material science aim to develop different types of silicones that are extremely durable, flexible, and resistant to impact in extreme weather or harsh environments. This means that they can be used in very harsh conditions, from industrial use to highly flexible residential.

As the industry develops, the level of technology continues to improve and the applications are becoming more diverse to meet the growing demand for unique and customized sealants. This will prompt manufacturers to adopt flexible production lines to provide customized formulations while ensuring product quality. This flexibility will undoubtedly enhance the end-user experience and increase competitive advantage in a competitive market. The future of silicone sealant technology is bright - they herald the arrival of a new era of efficiency and sustainability.