Inquiry

Form loading...

In the world of construction and crafting, adhesive solutions play a pivotal role. Among the myriad options available, Transparent Liquid Nails emerge as a standout choice for both professionals and DIY enthusiasts alike. These versatile adhesives provide a seamless bond that is not only strong but also aesthetically pleasing, ensuring that the integrity of any project remains intact. Understanding the best uses of Transparent Liquid Nails can transform the way one approaches both simple home repairs and complex building endeavors.

As we dive deeper into the topic, we will explore the various applications of Transparent Liquid Nails, from securing trim and molding to facilitating intricate art projects. Additionally, we will offer practical tips on how to maximize their effectiveness and ensure a successful bond. The benefits of using Transparent Liquid Nails extend beyond their appearance; they also include ease of use, quick setting times, and superior flexibility. Join us as we unveil the top insights and advice for making the most out of Transparent Liquid Nails in your next creative or construction adventure.

Transparent liquid nails have evolved significantly in recent years, offering enhanced performance and versatility in various applications. One of the key characteristics of these innovative adhesives is their ability to bond seamlessly with multiple surfaces, including wood, metal, glass, and plastics. This versatility makes them ideal for both indoor and outdoor projects, allowing users to achieve a clean, invisible finish that reduces the need for visible fasteners. In addition, their quick drying time and strong holding power are essential features, ensuring that projects can be completed efficiently without sacrificing durability.

Innovation in transparent liquid nails has also led to the development of formulas that are more user-friendly and environmentally conscious. Many of these products now feature low VOC (volatile organic compound) formulations, which contribute to a safer working environment and minimize harmful emissions. Furthermore, advancements in application technology, such as precision nozzles and easy-squeeze tubes, allow for accurate placement and reduce waste. These characteristics not only enhance the user experience but also ensure that the final product meets the demands of modern building and crafting needs, proving that transparent liquid nails are essential tools for both professional contractors and DIY enthusiasts alike.

This chart illustrates key performance metrics of transparent liquid nails, highlighting their adhesion strength, drying time, flexibility, water resistance, and heat resistance. Each characteristic is vital for assessing the effectiveness and suitability of the adhesive for various applications.

Transparent liquid nails have gained significant traction across various industries due to their versatility and strong bonding capabilities. In the construction sector, these adhesives are essential for bonding materials such as wood, metal, and plastics. A report from Transparency Market Research indicates that the global adhesive market is projected to reach $60 billion by 2025, with the use of liquid adhesives increasing by 4.5% annually. This growth is driven by the need for efficient and lasting solutions that can withstand diverse environmental conditions.

In the automotive industry, transparent liquid nails are particularly advantageous for repair and assembly processes. They offer the ability to bond different substrates seamlessly, which is crucial when working with modern lightweight materials and complex vehicle designs. According to a study by MarketsandMarkets, the automotive adhesives segment is estimated to grow at a CAGR of 5.9%, highlighting the increasing reliance on advanced adhesives for enhanced performance and durability in vehicle manufacturing.

Additionally, the craft and DIY sectors benefit greatly from transparent liquid nails, providing hobbyists and professionals with an effective means to create projects with a clean finish. Surveys have shown that approximately 70% of DIY enthusiasts consider strong adhesive properties as a priority when selecting crafting materials. Thus, transparent liquid nails not only fulfill industrial needs but also cater to the growing trend of personalized crafts and home improvements, making them an indispensable tool in various applications.

| Application Area | Best Use Cases | Benefits | Tips for Use |

|---|---|---|---|

| Construction | Attaching trim and molding | Strong bond, quick-drying | Ensure surfaces are clean and dry |

| Arts and Crafts | DIY projects and repairs | Versatile application, transparent finish | Use sparingly for better control |

| Automotive | Sealing gaskets and joints | Weather-resistant, durable | Test adhesion before extensive use |

| Furniture Repair | Fixing broken parts and joints | Invisible repair, easy application | Clamp joins for stronger hold |

| Home Decor | Attaching decorations and fixtures | Clean application, aesthetic appeal | Use in well-ventilated areas |

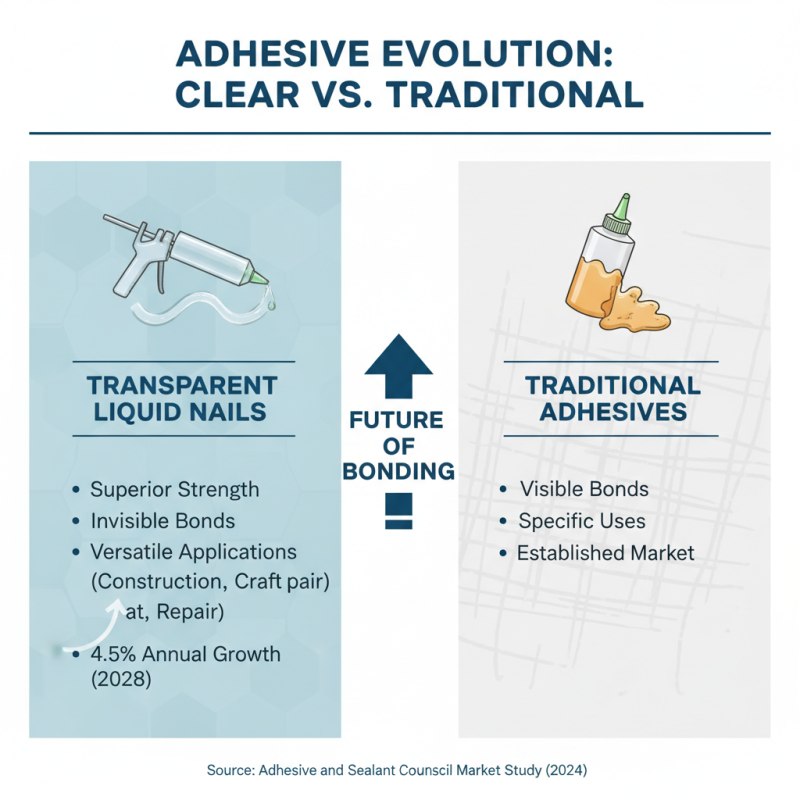

When considering adhesive options, the choice between transparent liquid nails and traditional adhesives is pivotal for various applications. Transparent liquid nails have gained popularity in recent years due to their superior bonding strength and versatility. According to a recent market study conducted by the Adhesive and Sealant Council, the demand for clear adhesives is expected to grow by 4.5% annually through 2028, driven by their aesthetic appeal and functional benefits in construction, craft, and repair applications. By providing invisible bonds, these adhesives ensure that joint aesthetics are preserved, especially in visible areas.

In contrast, traditional adhesives often include messy formulations that can mar the surface of the materials they bind. A 2022 report from the Construction Materials Association indicated that nearly 30% of contractors prefer transparent liquid nails for their ease of application and clean finish. Clear adhesives also exhibit impressive durability, with resistance to moisture and temperature fluctuations — qualities that are essential in environments subject to varying conditions. Furthermore, transparency allows for greater flexibility in design and crafting, as it blends seamlessly into various materials without detracting from the overall appearance.

With such compelling advantages, transparent liquid nails not only meet the needs of rigorous construction tasks but also appeal to DIY enthusiasts looking for reliable solutions without compromising on aesthetics.

When using transparent liquid nails, adhering to best practices can significantly enhance your project outcomes. First and foremost, surface preparation is crucial. According to a report by the Adhesive and Sealant Council, over 50% of adhesive failures are linked to improper surface cleaning and preparation. Ensure that surfaces are clean, dry, and free from grease or dust. For porous materials, a primer may be necessary to improve adhesion, as this can help the adhesive bond more effectively and provide a stronger hold.

Another key tip is to apply the adhesive in a consistent bead for even coverage. The ideal application method depends on the surfaces being bonded; for vertical applications, a thicker bead can prevent slippage during curing. It's recommended to allow adequate curing time before stressing the bond, with most transparent liquid nails requiring 24 hours to reach full strength. Additionally, consider ambient temperature and humidity, as these environmental factors can influence the performance of the adhesive. The American Society for Testing and Materials (ASTM) notes that excessive moisture can compromise adhesion, so it’s best to work in dry conditions when possible. By following these guidelines, users can maximize the effectiveness of transparent liquid nails for a variety of applications, from home repairs to artistic projects.

Transparent liquid nails, a versatile adhesive solution, are gaining popularity due to their environmental and performance benefits. Unlike traditional adhesives that often contain harmful solvents, many transparent liquid nails are now formulated with eco-friendly ingredients. According to a recent report by the Adhesive and Sealant Council, around 80% of new adhesive formulations are compliant with low-VOC (Volatile Organic Compounds) regulations, significantly reducing air pollution and contributing to healthier indoor environments. This shift not only supports sustainability goals but also enhances user safety during application.

One of the key performance factors of transparent liquid nails is their strong bonding capability across various materials. They are particularly effective for bonding porous and non-porous materials, offering an excellent alternative for construction and home improvement projects. Users can benefit from an increase in durability and moisture resistance, making them ideal for both indoor and outdoor applications. A study from the Construction Specifications Institute highlights that adhesives with high transparency and excellent adhesion properties have a 30% longer lifespan compared to typical bonding solutions.

When using transparent liquid nails, proper application is crucial. Here are some tips: first, ensure that surfaces are clean and dry to promote optimum adhesion. Second, apply the adhesive evenly to prevent any weak spots. Finally, allow for adequate curing time as specified by the manufacturer—this can enhance the bond strength significantly. Following these tips can lead to superior results and extend the longevity of your projects.