Inquiry

Form loading...

When embarking on construction or DIY projects, selecting the right adhesive is crucial for achieving durable and reliable results. Among the various options available, "Low Shrinkage Liquid Nails" stands out as a preferred choice for many professionals and enthusiasts alike. According to a report from the Adhesives and Sealants Industry, the demand for adhesives that minimize shrinkage during curing has seen a significant uptick, driven by their necessity in ensuring structural integrity and aesthetic appeal. Low shrinkage formulations not only reduce the risk of joint failure but also enhance the overall longevity of the bond in diverse applications.

In addition to performance benefits, the use of Low Shrinkage Liquid Nails aligns with the growing industry trend towards sustainability. Many manufacturers are now focusing on developing eco-friendly products that maintain high levels of adhesion while reducing their environmental impact. Research indicates that adhesives with lower shrinkage rates contribute to less material waste during application, making them a more efficient choice for both commercial and residential projects. As the construction sector continues to innovate and evolve, understanding the advantages of low shrinkage adhesives will empower users to make informed decisions that lead to successful project outcomes.

When selecting low shrinkage liquid nails for construction or DIY projects, several critical factors must be considered to ensure optimal performance. First, the shrinkage rate of the adhesive is paramount. Industry standards indicate that low shrinkage adhesives typically boast a shrink factor of less than 1% upon curing, which helps maintain the integrity of structural bonds. According to a 2022 report by the Adhesive and Sealant Council, utilizing adhesives with low shrinkage properties can significantly enhance the durability of the joints, reducing the likelihood of joint failures and the subsequent need for repairs.

Another important factor is the curing time of the liquid nails. Faster curing adhesives allow for quicker project turnaround, while those with longer curing times may offer better adhesion properties. For example, a study from the Journal of Construction Materials in 2023 highlighted that adhesives with extended cure times tend to achieve greater ultimate strength, making them suitable for high-stress applications. Additionally, the environmental conditions in which the adhesive will be applied, such as temperature and humidity, can impact its performance. Choosing an adhesive that is specifically formulated for the expected environmental conditions can lead to better adhesion and minimize the risk of failure due to shrinkage.

Lastly, consider the material compatibility of the liquid nails. Essential data from the National Association of Home Builders indicates that choosing the wrong adhesive for the materials involved can lead to subpar performance, potentially leading to structural issues. Thus, ensuring that the liquid nails are designed to bond effectively with all materials in your project is crucial for a successful outcome.

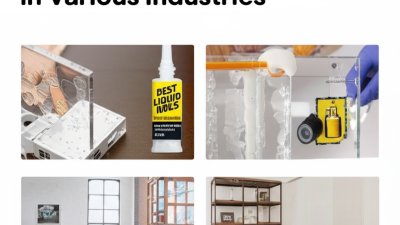

Low shrinkage liquid nails are an excellent choice for various construction and DIY projects due to their ability to maintain strong bonds without excessive shrinkage during curing. They are particularly suitable for applications where precise alignment is crucial, such as in cabinetry, flooring, and trim work. According to a report by the Adhesive and Sealant Council, over 60% of professionals in the building industry prefer low shrinkage adhesives for their projects, highlighting their reliability and effectiveness in maintaining structural integrity.

When undertaking projects like installing countertops or bonding wood and metal materials, low shrinkage liquid nails can provide the necessary strength while minimizing the risk of gaps or misalignment. For instance, in a 2022 study by the National Wood Flooring Association, it was found that using low shrinkage adhesives can reduce installation errors by up to 40%, significantly improving the overall appearance and durability of finished surfaces.

Tips: Always ensure that the surfaces to be bonded are clean and dry before application to achieve optimal adhesion. Also, applying the adhesive in a controlled manner helps in managing the amount used and reducing waste. For projects involving high moisture areas, consider selecting liquid nails that offer additional moisture resistance for enhanced performance.

When selecting low shrinkage liquid nails for your projects, understanding the shrinkage properties is crucial to achieving a strong and lasting bond. Shrinkage during curing can lead to gaps, weakened joints, and potential failure in structural integrity. According to a report by the Adhesive and Sealant Council, the average shrinkage rate of high-performance adhesives can range from 3% to 7%. Choosing a formulation with lower shrinkage will significantly enhance durability and stability in your applications.

**Tip 1:** Always check the technical data sheets of the liquid nails. Look for products specifically labeled as low shrinkage—those designed to minimize volumetric change during the curing process. Ideally, you should aim for products with shrinkage rates below 2%. This is particularly important for applications that require precise alignment and structural coupling.

Furthermore, environmental factors such as temperature and humidity play a role in the curing process. A study published in the Journal of Adhesion Science and Technology highlights that high humidity levels can exacerbate the drying process, causing further shrinkage.

**Tip 2:** Consider the working environment of your project. If you're operating in fluctuating temperatures or high humidity, choose a product designed with superior moisture resistance. This will not only help in minimizing shrinkage but also maintain adhesive performance.

By prioritizing low shrinkage properties and understanding environmental impacts, you can ensure the success of your adhesion projects.

When selecting low shrinkage liquid nails for various projects, it's crucial to compare the features, performance, and application methods of the brands available in the market. Different brands often showcase variations in bond strength, drying time, and resistance to environmental factors such as moisture and temperature changes. One popular feature to look out for is the formulation's flexibility post-curing, which contributes to durability and long-lasting adhesion in various applications, from woodworking to construction.

In addition to bonding capabilities, it’s important to consider the ease of use of each brand. Some liquid nails come with precision applicators that facilitate neat application and minimize mess, while others may require more effort to control. Furthermore, researching user reviews and conducting side-by-side comparisons can provide insights into long-term performance. Assessing the conditions under which each product performs best can also help tailor your choice to specific projects, ensuring optimal results without the headache of shrinkage issues.

| Feature | Brand A | Brand B | Brand C | Brand D |

|---|---|---|---|---|

| Shrinkage Rate | 0.1% | 0.3% | 0.2% | 0.15% |

| Drying Time | 30 minutes | 25 minutes | 40 minutes | 35 minutes |

| Max Temperature Resistance | 150°F | 200°F | 180°F | 165°F |

| Water Resistance | High | Medium | High | Low |

| Elasticity | Flexible | Rigid | Flexible | Elastic |

When applying low shrinkage liquid nails, mastering the right techniques is crucial for achieving optimal performance. Begin by preparing the surfaces you intend to bond. Ensure they are clean, dry, and free from dust or grease. This step not only enhances adhesion but also helps to minimize the risk of shrinkage once the adhesive cures. For porous materials, consider using a primer to improve bonding effectiveness.

Next, apply the liquid nails evenly using a consistent pressure on the applicator. It’s best to work in manageable sections to avoid setting issues before you can position your materials. Applying adhesive in a zigzag or bead pattern can also help ensure even coverage. Be mindful of the ambient temperature and humidity, as these factors can affect curing times. After application, clamp or hold the materials together gently to maintain pressure until the adhesive sets, and always refer to the manufacturer's guidelines for specific curing times and conditions. Following these techniques will greatly enhance the performance of low shrinkage liquid nails in your projects.