Inquiry

Form loading...

Insolating Glass Silicon Glue has emerged as a critical component in the glass manufacturing sector. This adhesive plays a vital role in enhancing the insulation properties of glass. According to a recent market analysis, the global silicon adhesive market is projected to reach $9 billion by 2025. Such growth highlights the increasing demand for high-performance adhesives.

This specialized glue is particularly effective in applications like windows and facades. It helps create energy-efficient buildings. The use of Insolating Glass Silicon Glue can lead to a significant decrease in energy consumption. However, its effectiveness relies on proper application techniques. Many manufacturers still face challenges in achieving optimal adhesion and insulation performance.

Despite its benefits, there is room for improvement in awareness about the proper usage of Insolating Glass Silicon Glue. Research indicates that up to 30% of installations may not meet industry standards. This gap points to the necessity for better training and resources. Ultimately, understanding this adhesive can lead to better building practices and improved energy efficiency in architecture.

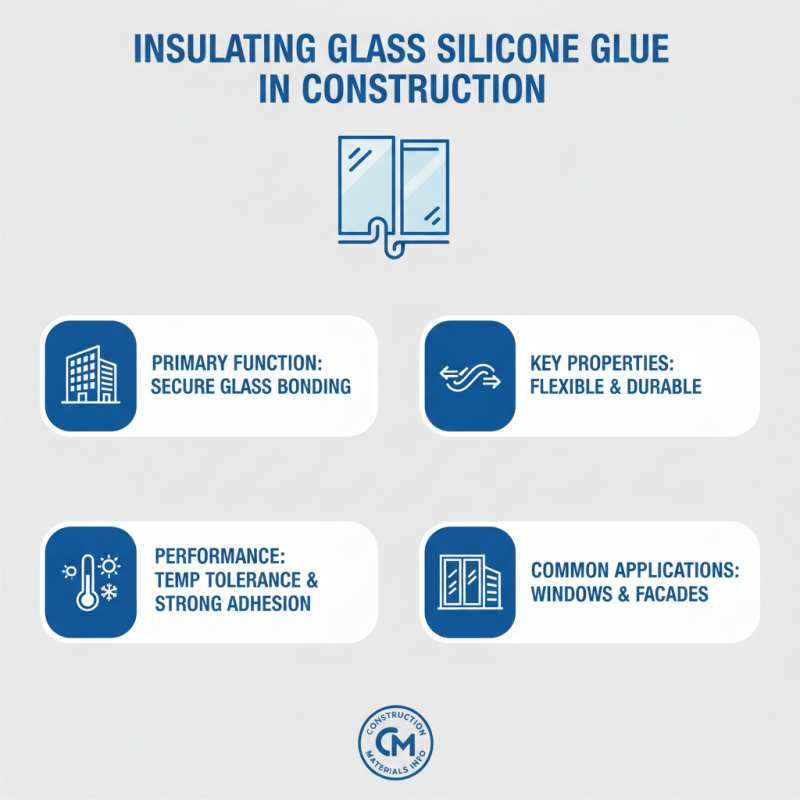

Insolating glass silicon glue is a unique adhesive designed specifically for glass applications. This glue has properties that allow it to bond glass effectively, creating a strong seal. It is often used in windows, solar panels, and decorative glass items. Its flexibility is crucial, especially with temperature changes that can cause materials to expand or contract.

This glue is clear, which ensures that the transparency of glass remains unchanged. When applying this adhesive, it is essential to work in a well-ventilated area. Mistakes can happen, such as uneven application or inadequate curing time. These issues can lead to weak bonds. It’s important to follow the guidelines carefully and allow the correct drying time.

Moreover, the versatility of insulative silicon glue extends beyond simple bonding. It provides weather resistance and can withstand harsh environmental conditions. Users often appreciate its ability to form a waterproof barrier. However, some may face challenges with cleanup if excess glue is not removed promptly. Learning the proper techniques takes time and practice, but the results can be rewarding.

Insolating glass silicon glue is a crucial material in modern construction and manufacturing. This glue is designed to bond glass to other materials tightly. It also provides insulation against heat and sound. The components that make this glue effective contribute to its versatility.

The primary ingredients include silicone polymers, fillers, and curing agents. Silicone polymers give the glue its flexibility and durability. Fillers are added to enhance its strength and thermal insulation properties. Curing agents help the glue harden and properly adhere to surfaces. These components work together to create a robust adhesive that resists moisture and environmental stress.

While insolating glass silicon glue has many advantages, there are challenges in its application. It requires careful mixing and proper conditions to cure effectively. Any mistakes in the process can lead to weak bonds. Users must also be aware of the curing time, which can vary. Each project may demand unique considerations for achieving the best results.

| Component | Description | Functionality |

|---|---|---|

| Silicone Polymer | A flexible, durable polymer that provides elasticity and bonding capabilities. | Seals and bonds glass in various applications. |

| Adhesives | Substances used to bind two surfaces together. | Ensures strong adhesion between glass and frames. |

| Curing Agents | Chemicals that promote the hardening of the adhesive. | Facilitates the setting process of the silicone glue. |

| Fillers | Materials added to enhance properties such as viscosity. | Improves the application and performance of the glue. |

| Pigments | Coloring agents used to achieve desired aesthetic properties. | Affects the visual aspect of the finished product. |

Insolating glass silicon glue is often used in construction. Its main function is to bond glass panels securely. This glue is flexible and durable. It tolerates changes in temperature and supports strong adhesion to various surfaces. Builders prefer it for windows and facades.

Using insolation glue in construction has many applications. It provides insulation, reducing energy costs. In commercial buildings, it protects against weather elements. The flexibility helps absorb vibrations. This glue is essential for high-rise buildings that deal with wind pressure.

Tips: Always apply the glue evenly. Uneven application can lead to leaks. Ensure surfaces are clean and dry before bonding. Test small areas first. This helps you gauge how the glue reacts with materials. When using large amounts, consider safety measures. Proper ventilation is key to avoid inhalation of fumes.

Insolating glass silicon glue has gained popularity for its unique advantages. This adhesive offers excellent insulation properties, making it ideal for sealing windows and other glass structures. It helps maintain temperature control, reducing energy costs and improving comfort. The flexibility of this glue allows it to absorb movement, preventing cracks or leaks over time.

Using this type of silicon glue means fewer repair needs. It creates a strong bond, ensuring durability while being resistant to moisture and harsh weather. Over time, however, some users notice that the adhesive may yellow or degrade with exposure to UV light. This slight downside reminds us to consider the environment where this glue will be applied.

Another benefit lies in its ease of application. The glue can be applied without special tools. However, achieving a clean finish may require practice. Users often find they need to wipe away excess glue carefully. This process highlights the importance of precision when working with adhesives. Small mistakes may lead to unsightly results that can affect overall aesthetics.

Insolating glass silicon glue is essential for various applications. This adhesive is known for its durability and resistance to environmental factors. Proper application is key to ensuring optimal performance. To achieve the best results, specific tips should be considered.

When applying insolating glass silicon glue, surface preparation is critical. Clean the surfaces thoroughly to remove dust and grease. Use isopropyl alcohol for cleaning. Avoid applying the glue in high humidity conditions. The ideal temperature range is between 50°F and 100°F. This information comes from recent industry reports showing improved adhesion rates when applied under optimal conditions.

After applying the glue, allow it to cure fully. Some products may require up to 24 hours for a complete bond. Inadequate curing time can lead to bond failure. Use a caulking gun for precise application. This method ensures a controlled bead without excess waste. Remember, patience is crucial as rushing can compromise the integrity of the seal.