Inquiry

Form loading...

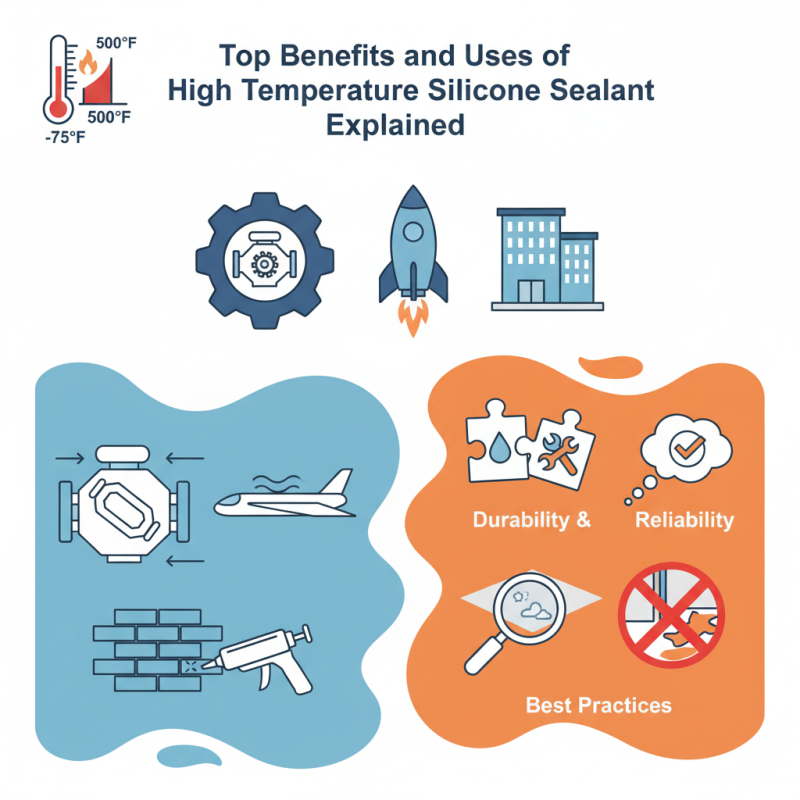

High Temperature Silicone Sealant is a versatile and essential material in various industries. Its unique properties make it suitable for extreme conditions. This sealant can withstand temperatures ranging from -75°F to 500°F. Often used in automotive, aerospace, and construction applications, it ensures durability and reliability.

In automotive sectors, High Temperature Silicone Sealant is critical for engine components. It binds parts and prevents leaks in high-heat areas. Similarly, in aerospace, it offers insulation and thermal protection. Its ability to maintain integrity under pressure is remarkable.

However, using High Temperature Silicone Sealant requires caution. Improper application may lead to issues like inadequate bonding. It is crucial to prepare surfaces properly. Users should take time to ensure a clean application. Reflecting on best practices improves results significantly. Understanding the limitations of the sealant can help in achieving optimal performance.

High temperature silicone sealant offers unique advantages for various applications. It's designed to withstand extreme heat, making it ideal for automotive, aerospace, and industrial settings. These sealants maintain flexibility and adhesion even when exposed to temperatures exceeding 500°F. Such performance is crucial for regions experiencing thermal changes.

The versatility of high temperature silicone sealant is impressive. It can bond metal, glass, and ceramics effectively. Users often find it useful in sealing gaps and joints in ovens and heaters. The quick curing time allows for efficient project completion. However, not all projects use it effectively. Some might underestimate its curing process or overapply, leading to mess and inefficiency.

In many cases, careful application ensures durability and effectiveness. Surface preparation plays a vital role here. A clean, dry surface enhances adhesion. Yet, users sometimes overlook this step, leading to premature failures. Reflecting on these practices helps improve overall outcomes in future projects.

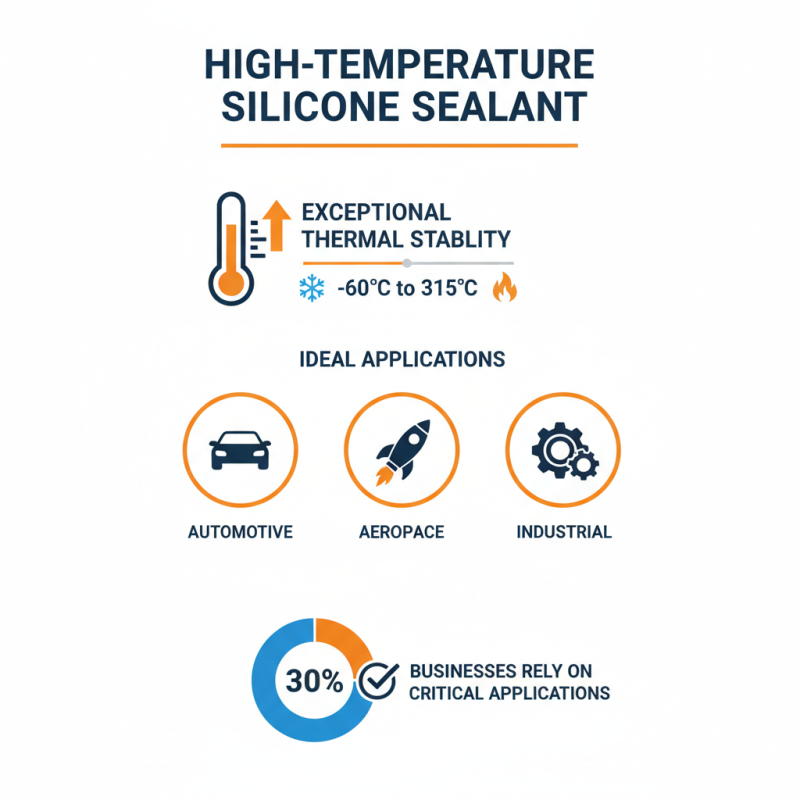

High temperature silicone sealant is unique due to its exceptional thermal stability. It typically withstands temperatures ranging from -60°C to 315°C. This makes it ideal for applications in automotive, aerospace, and industrial sectors. A recent industry report highlighted that nearly 30% of businesses rely on high temperature silicone sealants for critical applications.

These sealants also possess excellent adhesion properties, binding effectively to metals, glass, and most plastics. They create a flexible seal that resists cracking and hardening over time. This durability is crucial in high-stress environments, where other sealants might fail.

**Tips:** Always clean surfaces before application. This ensures maximum adhesion. Check for compatibility; not all materials interact well. Certain environments can expose sealants to various chemicals, so verifying chemical resistance is essential. Address any uncertainties early on.

High temperature silicone sealant is versatile. It is widely used in various applications. One of its common uses is in automotive industries. It effectively seals engine components under high heat and pressure. This sealant can endure extreme temperatures, often exceeding 500°F. It also prevents leaks, which is critical when dealing with engine fluids.

Another notable application is in construction. High temperature silicone is ideal for chimney and stove pipe installations. It can withstand high heat from fireplace environments. Many people rely on it for sealing HVAC ducts, too. This prevents air leaks, improving energy efficiency in buildings. Using it correctly requires careful application, which can be challenging. Uneven surfaces or incorrect methods can lead to failure over time.

Household uses also abound, especially in kitchens. It's suitable for sealing around ovens or stovetops. However, it may not always adhere well to some surfaces. Proper cleaning and surface preparation are essential for strong bonds. Users must be aware of these details, or the sealant may not perform as expected.

| Benefit/Use | Description | Common Applications |

|---|---|---|

| High Temperature Resistance | Can withstand extreme temperatures without degrading. | Automotive, Aerospace, Industrial Ovens |

| Flexibility | Remains flexible after curing, enabling it to absorb vibrations. | Engine components, Appliance assembly |

| Durability | Resistant to weathering, moisture, and UV radiation. | Outdoor applications, Marine environments |

| Adhesion | Strong adhesion to a variety of surfaces including metal, glass, and plastics. | Pipe sealing, HVAC systems |

| Chemical Resistance | Resistant to many chemicals and solvents, enhancing longevity. | Chemical processing industries, Oil and gas sectors |

High temperature silicone sealant is known for its exceptional durability. This material withstands extreme temperatures, often up to 500°F (260°C). It shines in applications like automotive sealing and cooking appliances. It's flexible, which allows it to absorb movement and vibrations effectively. This makes it ideal for areas exposed to constant heat changes.

Another key advantage is its resistance to moisture and chemicals. High temperature silicone works well in both dry and humid environments. It prevents leaks and protects against corrosion. However, ensuring a proper application requires attention. If applied incorrectly, it may not adhere well or seal effectively. Regular checks can help maintain its integrity over time.

The easy application is also appealing. It can be used on various surfaces, from metals to ceramics. A caulking gun is usually all that’s needed. Yet, improper surface preparation can lead to adhesion failures. So, take the time to clean and prime surfaces. Inadequate drying time can also compromise its efficiency.

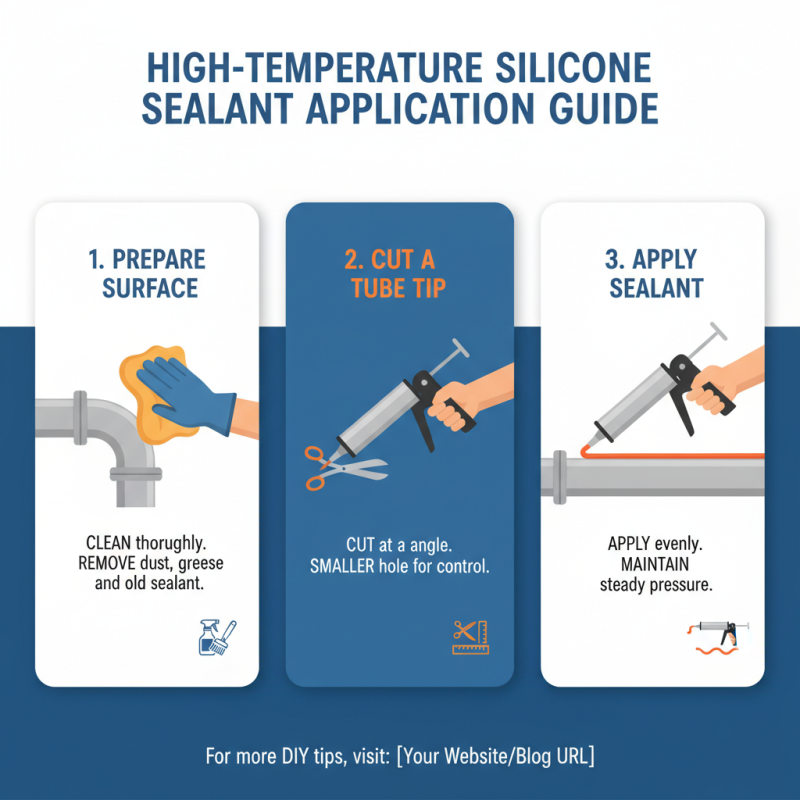

Applying high temperature silicone sealant can seem straightforward, but it requires careful attention. Always prepare the surface by cleaning it thoroughly. Dust and grease can ruin the bond. Cut the tip of the tube at an angle for better application. A smaller hole allows for precise control when sealing.

Tips for proper application include using a caulking gun for consistent pressure. Hold the nozzle at a 45-degree angle to ensure a smooth bead. Move steadily to avoid gaps. If you make a mistake, wipe away excess silicone quickly before it sets. It’s easier to fix it right away rather than deal with it later.

Maintenance is also vital for long-lasting results. Regularly inspect your sealed areas for any signs of wear. If you notice cracks or peeling, reapply silicone as needed. Store any leftover sealant in a cool, dry place, but remember it has a shelf life. Using old sealant may lead to bonding issues. Pay attention to these details, and your projects will last longer.