Inquiry

Form loading...

In the rapidly evolving landscape of construction and DIY projects, the demand for reliable and efficient bonding solutions continues to rise. Fast Grab Adhesives have emerged as a critical component in achieving timely and effective results. According to industry expert Dr. Emily Carter, a renowned materials scientist, "The future of construction will be defined by the speed and reliability of adhesive solutions. Fast Grab Adhesives are revolutionizing how we approach both small-scale projects and large developments."

As we look toward 2025, innovative advancements in Fast Grab Adhesives are set to transform the way professionals and hobbyists alike tackle their projects. With shorter curing times and increased bonding strength, these adhesives offer practical solutions for a variety of materials, making them indispensable in modern constructions. Furthermore, as sustainability becomes a pressing concern, the development of eco-friendly Fast Grab Adhesives presents new possibilities for versatile applications that not only perform but also adhere to environmentally conscious standards.

With insights from thought leaders like Dr. Carter and a focus on the latest trends, this guide aims to explore the top Fast Grab Adhesive tips for 2025, enabling you to efficiently elevate your project outcomes while embracing the future of adhesive technology.

When it comes to enhancing your projects in 2025, choosing the right fast grab adhesive is essential. The innovations in adhesive technology have led to varieties specifically designed for different materials, ensuring that you achieve the strongest bond while saving time. From wood to metal, and even delicate materials, there’s an adhesive type tailored for your needs.

One key tip when working with fast grab adhesives is to consider the surface preparation. Clean and dry surfaces allow the adhesive to bond more effectively, reducing the chances of failure. For porous materials like wood, using a primer can also improve adherence. Another vital tip is to pay attention to the working time of the adhesive. Some products offer rapid curing, while others may require a bit more time to set. Knowing these details can help you plan your projects more efficiently.

Lastly, always follow the manufacturer's application instructions for best results. Different adhesives may come with unique application methods or specific environmental conditions for curing. By adhering to these guidelines, you can ensure your projects not only hold up well but also look polished and professional. Whether it’s a DIY home improvement project or crafts, understanding the various types of fast grab adhesives available can undeniably transform your results.

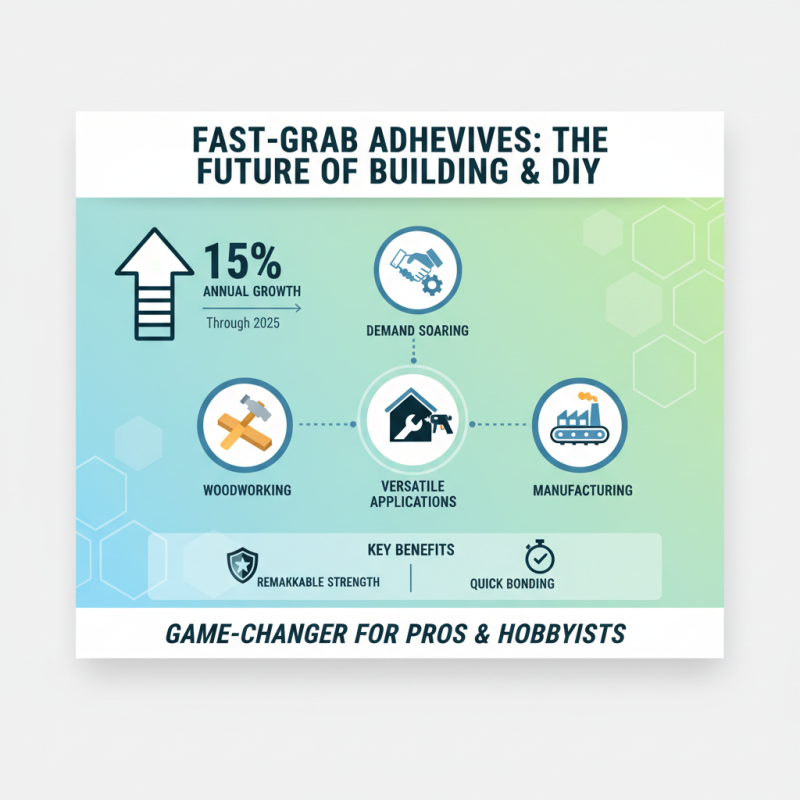

In the rapidly evolving landscape of construction and DIY projects, the advancement of high-performance fast grab adhesives has become a game changer. These adhesives, characterized by their remarkable strength and quick bonding capabilities, are now essential tools for both professionals and hobbyists alike. Recent industry reports highlight that the demand for fast grab adhesives is projected to grow by 15% annually through 2025, driven by their versatility and efficiency in various applications, including woodworking, home repairs, and manufacturing.

Key properties of these adhesives include excellent bonding strength, rapid curing time, and resistance to temperature fluctuations and moisture. These features make them ideal for challenging environments where traditional adhesives may fail. Furthermore, many fast grab adhesives are now designed with user-friendly application methods, allowing for quick setups and clean finishes. This shift not only enhances productivity but also improves the overall quality of finished projects.

When selecting a fast grab adhesive, consider these tips: first, assess the material compatibility to ensure optimal binding performance; second, prioritize adhesives with low VOC emissions for a safer working environment; and lastly, examine the open time of the adhesive, which dictates how long you have for adjustment before it sets. Utilizing these insights can significantly elevate the success of your adhesive projects, ensuring durability and reliability in your outcomes.

In 2025, the effective application of fast grab adhesives can significantly enhance project efficiency and outcomes. Understanding the optimal techniques for application is essential for maximizing adhesive performance. According to a recent industry report by the Adhesive and Sealant Council, proper surface preparation increases adhesion strength by up to 30%. Ensuring surfaces are clean, dry, and free from contaminants allows for a stronger bond and helps achieve quicker curing times.

To optimize fast grab adhesive performance, it’s crucial to apply the adhesive evenly. Utilizing a caulking gun ensures consistent bead formation, which minimizes air pockets that can weaken the bond. Additionally, applying pressure immediately after the adhesive is placed can help improve initial bond strength. It's also recommended that a test batch be carried out before full application, helping to gauge the adhesive setting time and ease of manipulation, thereby averting costly mistakes.

When working in various environmental conditions, consider that temperature and humidity levels can affect drying times. It has been shown that adhesives generally cure faster in warmer and drier environments. For projects requiring immediate use, selecting a fast-setting formula with co-reactive components can drastically cut down on wait times, allowing projects to proceed without prolonged delays.

When utilizing fast grab adhesives, safety should always be a top priority. Recent industry reports indicate that adhesive accidents account for up to 19% of workplace injuries related to materials handling. Therefore, employing proper safety practices is essential. Always use adhesives in well-ventilated areas to minimize inhalation hazards, as prolonged exposure to fumes can lead to respiratory issues. Personal protective equipment (PPE), such as gloves and safety goggles, should be worn to protect your skin and eyes from potential irritants.

Additionally, understanding the specific properties of fast grab adhesives can significantly enhance both safety and effectiveness. These adhesives typically offer high initial grab strength, allowing for quick bonding and less repositioning time. However, this characteristic requires operators to be precise in their application. Misalignment can lead to wasted materials and safety risks from improper bonding. According to the Adhesive and Sealant Council, improper use of adhesives results in an estimated 30% of project failures, underscoring the importance of following manufacturers' guidelines. By adhering to these best practices and focusing on safety, users can ensure successful outcomes in their adhesive projects.

| Tip | Description | Safety Precautions | Best Practices |

|---|---|---|---|

| Use in Well-Ventilated Areas | Ensure proper airflow to reduce inhalation of fumes. | Wear a mask if necessary. | Open windows and use fans for ventilation. |

| Check for Surface Compatibility | Ensure the adhesive is suitable for the surfaces you are using. | Follow the manufacturer's guidelines regarding materials. | Test a small area first if unsure. |

| Storage in a Cool, Dry Place | Store adhesives to maintain their efficacy over time. | Avoid exposure to extreme temperatures. | Keep out of reach of children. |

| Use Gloves for Application | Protect your hands from adhesive residue. | Choose chemical-resistant gloves. | Be careful to avoid skin contact. |

| Read Instructions Thoroughly | Understand the product before use. | Follow all safety warnings and instructions. | Refer to the FAQs if available. |

As the demand for efficient and user-friendly materials in DIY projects continues to rise, the future of fast grab adhesives is poised to undergo significant transformation. Innovations in adhesive technology are focusing on formulations that enhance bond strength while decreasing drying time, making these products ideal for various applications—from crafts to home improvements. The incorporation of eco-friendly ingredients is also expected to gain traction, catering to the growing audience that prioritizes sustainability in their projects. This trend toward environmentally conscious products will likely reshape consumer preferences and drive market competition.

In addition to more sustainable compositions, future fast grab adhesives may also feature improved application techniques. Advancements in nozzle design and packaging could allow for more precise application, minimizing waste and enhancing user experience. Incorporating smart technology into these products could further revolutionize the DIY sector, with adhesives that change color to indicate optimal bonding conditions or self-repair capabilities for temporary fixes. As these trends emerge, DIY enthusiasts can look forward to a new era of crafting solutions that not only meet their project needs but also align with broader environmental goals.