Inquiry

Form loading...

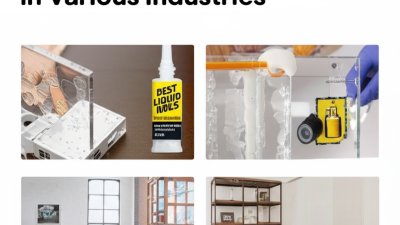

When embarking on a construction project, the right materials make all the difference. One such essential material is Strong Construction Adhesive, a versatile solution that can bond a variety of surfaces with exceptional durability. Whether you're working on woodworking, home improvement, or industrial applications, understanding how to use this powerful adhesive effectively can lead to better results and a smoother workflow.

In this guide, we will explore ten essential tips that will help you maximize the benefits of Strong Construction Adhesive. From preparing surfaces and selecting the right type of adhesive to applying techniques and curing times, these insights will ensure that your projects are not only successful but also long-lasting. Mastering the use of Strong Construction Adhesive is key to achieving strong bonds and a professional finish, making it a vital skill for anyone involved in construction or DIY endeavors. Let's dive into the specifics that will elevate your adhesive application process.

When selecting the right strong construction adhesive for your project, it's essential to consider the materials you will be bonding. Different adhesives are formulated to perform optimally with specific materials, so understanding the compatibility is crucial. For example, some adhesives work best with wood, while others excel in bonding metal, plastic, or fabric. Researching your materials and the properties of various adhesives can significantly enhance the effectiveness of your bond.

Additionally, versatility is an attractive feature when choosing a construction adhesive. Some multi-purpose adhesives can bond a wide range of surfaces, making them great for various applications. This means you won’t have to stock multiple types of glue for different projects, simplifying your process and saving time. Always make sure to read product specifications and user reviews to determine the best choice for your specific needs, ensuring a strong and durable bond every time.

Preparing surfaces properly is crucial for achieving maximum adhesive bonding when using strong construction adhesives. According to the Adhesive and Sealant Council, nearly 70% of adhesive failures can be attributed to inadequate surface preparation. Therefore, taking the time to ensure that surfaces are clean, dry, and free from contaminants is essential for developing a strong bond.

Before applying construction adhesive, it’s important to conduct a thorough cleaning of the surfaces involved. This can involve removing dirt, grease, dust, and old adhesives using appropriate solvents or cleaning agents. A study by the American Society of Civil Engineers highlighted that surfaces treated with isopropyl alcohol showed a 50% increase in bonding strength compared to untreated ones. Moreover, for porous materials, pre-sealing may be required to create a uniform surface that enhances adhesive performance.

Additionally, attention should be given to the surface texture. Smooth surfaces may require mechanical abrasion to increase adhesion, while rough surfaces often provide better bonding naturally. According to research from the International Journal of Adhesion and Adhesives, achieving a roughness depth of at least 100 microns can significantly affect the performance of adhesives used in construction. By focusing on these preparation techniques, professionals can ensure an optimal adhesive bond that stands the test of time.

This chart illustrates the bonding strength of construction adhesive based on different surface preparation techniques. Proper preparation significantly increases the adhesive's effectiveness, as shown by the varying levels of bonding strength measured in psi.

When using strong construction adhesives, proper application techniques are critical to achieving an even adhesive coverage, which ensures maximum bond strength and durability. According to a report by the Adhesive and Sealant Council, improper application can reduce the bond strength by up to 50%. To avoid this, it is essential to apply the adhesive evenly across surfaces using a notched trowel or roller, which can significantly improve the distribution and penetration of the adhesive.

It's also important to control the amount of adhesive used. A common mistake is over-application, which can lead to squeezing out and wasted materials. The American Institute of Architects suggests following manufacturer guidelines regarding adhesive application thickness, as most construction adhesives perform optimally at a specific range. Ensuring the surfaces are clean and dry before application further enhances adhesion, as contaminants can compromise the bond. By adhering to these techniques, users can maximize the effectiveness of strong construction adhesives and achieve robust, long-lasting results.

When using strong construction adhesive, it's crucial to consider both curing time and environmental factors to achieve optimal results. Factors like temperature, humidity, and air quality can significantly influence the curing process. For instance, adhesives generally cure faster in warm and humid conditions, while dry air can hinder the adhesive's performance, potentially leading to weaker bonds. According to industry studies, maintaining a controlled environment can reduce curing time by up to 50%, underscoring the importance of these variables.

To maximize the effectiveness of construction adhesives, here are a few essential tips:

Understanding the interplay of curing time and environmental factors is vital for successful adhesive application in any construction project.

When working with construction adhesives, avoiding common mistakes can greatly enhance the effectiveness of your project. A frequent error is not preparing the surfaces properly. Ensure that the surfaces are clean, dry, and free from dust or grease. This will allow the adhesive to bond more effectively, creating a stronger hold.

Another mistake is applying too much adhesive. While it might seem like a good idea to use extra adhesive, it can lead to a messy job and reduced bonding strength. Instead, apply a sufficient amount of adhesive evenly. Following this method will help in achieving a cleaner finish and a reliable bond.

Timing is also crucial. Failing to follow the recommended open time for the adhesive can compromise the bond. Rushing the application can lead to weak areas or incomplete adhesion. Always check the instructions for the specific adhesive you are using and allow for the proper curing time before putting stress on the bond. By keeping these tips in mind, you can avoid pitfalls and ensure a successful application of construction adhesives.

| Tip Number | Tip Description | Common Mistakes |

|---|---|---|

| 1 | Choose the Right Adhesive | Using an adhesive that is not suitable for the materials being joined. |

| 2 | Prepare Your Surface | Failing to clean and dry surfaces before applying adhesive. |

| 3 | Use Enough Adhesive | Applying too little adhesive, leading to weak bonds. |

| 4 | Follow Manufacturer Instructions | Ignoring specific instructions for curing time and application methods. |

| 5 | Consider Temperature and Humidity | Applying adhesive in unsuitable weather conditions. |

| 6 | Use Proper Tools | Using incorrect tools or methods for application. |

| 7 | Apply Evenly | Creating uneven application, which weakens the bond. |

| 8 | Allow Adequate Curing Time | Rushing the project by not allowing sufficient curing time. |

| 9 | Store Adhesive Properly | Failing to store adhesive according to guidelines, leading to reduced effectiveness. |

| 10 | Test on Small Area | Not testing adhesive on a small area before full application. |