Inquiry

Form loading...

In recent years, the demand for environmentally friendly construction materials has surged, with the global adhesive sealant market projected to reach $8.16 billion by 2026, according to a report by ResearchAndMarkets. Among the various options available, Water-Based Adhesive Sealants have gained significant attention due to their low volatile organic compound (VOC) emissions and ease of application. As more consumers and industries prioritize sustainability, understanding the key factors to consider when selecting these sealants becomes crucial.

This blog post will delve into five essential tips for choosing the right Water-Based Adhesive Sealant for your projects, ensuring optimal performance while adhering to eco-friendly practices. Proper selection not only enhances the durability of your applications but also supports a healthier environment for us all.

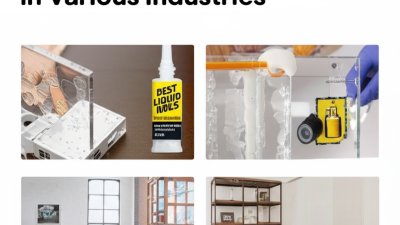

Water-based adhesive sealants have gained popularity in various projects due to their numerous benefits. One of the most significant advantages is their eco-friendliness. Unlike solvent-based sealants, water-based variants contain fewer volatile organic compounds (VOCs), making them safer for both the environment and human health. This feature is particularly appealing for indoor applications where air quality is a concern. Choosing a water-based sealant not only enhances project safety but also contributes to sustainable practices.

Another key benefit is the ease of use associated with water-based sealants. They can be easily cleaned up with soap and water, eliminating the need for harsh solvents. This user-friendly nature makes them accessible for both professionals and DIY enthusiasts. Moreover, water-based sealants can adhere effectively to a variety of surfaces, providing versatility in application. This adaptability ensures that projects ranging from home improvement to industrial applications can achieve a durable seal without compromising on efficiency or performance.

When selecting a water-based adhesive sealant for your project, several key factors demand consideration to ensure optimal performance and longevity. First and foremost, the adhesive's bonding strength is critical. According to a report by the Adhesive and Sealant Council, water-based sealants typically present lower initial adhesion compared to their solvent-based counterparts, but advancements in formulations have significantly improved their performance, making them suitable for a variety of applications, including construction and automotive sectors.

Another crucial aspect is the environmental impact. Water-based sealants are increasingly favored due to their low volatile organic compounds (VOCs) content, which is vital for indoor air quality. A survey conducted by the EPA highlights that the use of low-VOC products can reduce air pollution and foster a healthier living environment. Furthermore, considering the cure time can influence project timelines. Many water-based sealants now cure faster thanks to innovations in technology, allowing contractors to complete projects more efficiently. By evaluating these factors, you can select the right water-based adhesive sealant tailored to your specific needs.

| Factor | Description | Considerations |

|---|---|---|

| Compatibility | Ensure that the sealant is compatible with the materials being joined. | Check manufacturer specifications. |

| Application Method | Choose a sealant based on the application method: caulking gun, brush on, or spray. | Consider ease of use and project requirements. |

| Curing Time | Different sealants have varying curing times; some set quickly, while others require longer. | Plan your project timeline accordingly. |

| Temperature Resistance | Select a sealant that can withstand the temperature conditions of your project. | Check the temperature range listed in product specifications. |

| Environmental Impact | Consider sealants that are low in VOCs and environmentally friendly. | Look for certifications or eco-labels. |

When it comes to adhesive sealants, the choice between water-based and solvent-based products can significantly impact both performance and environmental safety. A 2021 report by the Adhesive and Sealant Council found that water-based sealants are growing in popularity, now comprising over 35% of the sealant market. This trend is largely due to their low volatile organic compounds (VOCs), making them a safer choice for indoor applications, unlike solvent-based sealants that can emit harmful fumes.

Additionally, water-based sealants offer excellent adhesion properties comparable to their solvent counterparts. According to a study published by the Journal of Adhesive Science and Technology, water-based sealants demonstrated similar tensile strength and durability in various conditions, including temperature fluctuations and humidity levels, making them suitable for both residential and commercial projects. However, it's important to consider the specifics of your project, such as substrate compatibility and expected exposure conditions, to maximize the effectiveness of your chosen adhesive sealant.

When working with water-based adhesive sealants, proper application techniques are crucial for achieving optimal performance. One key factor is surface preparation; according to a report from the Adhesive and Sealant Council, up to 70% of sealant failures can be traced back to inadequate surface cleaning. Removing contaminants such as dust, grease, or moisture not only ensures better adhesion but also enhances the longevity of the seal. A clean surface allows the sealant to bond effectively, which is vital when dealing with varying environmental conditions.

Another important technique is to apply the sealant at the right temperature and humidity levels. The American Society for Testing and Materials (ASTM) recommends maintaining a temperature range of 50°F to 100°F for optimal curing of water-based sealants. Furthermore, the application should ideally take place in relative humidity conditions between 30% to 80%. This helps achieve a proper cure rate and prevents issues such as blistering or improper adhesion. By paying attention to these critical application techniques, users can maximize the effectiveness of water-based adhesive sealants and ensure long-lasting results in their projects.

When working with water-based adhesive sealants, avoiding common mistakes can significantly enhance the quality and durability of your projects. One frequent error is neglecting surface preparation. Ensuring that surfaces are clean, dry, and free of contaminants will greatly improve adhesion and results.

When working with water-based adhesive sealants, avoiding common mistakes can significantly enhance the quality and durability of your projects. One frequent error is neglecting surface preparation. Ensuring that surfaces are clean, dry, and free of contaminants will greatly improve adhesion and results.

Another pitfall is not allowing enough drying time before exposing the sealant to stress. Many users underestimate the required curing time, which can compromise the effectiveness of the sealant. Always refer to the manufacturer's instructions to determine the proper time needed for the sealant to achieve optimal performance.

Additionally, it's vital to choose the right product for your specific application. Not all water-based sealants are created equal; some are better suited for indoor use, while others work well outdoors or in high-humidity areas. Consider the project's environment and demands before making your selection. Remembering these tips will help you utilize water-based adhesive sealants effectively and avoid costly mistakes.