Inquiry

Form loading...

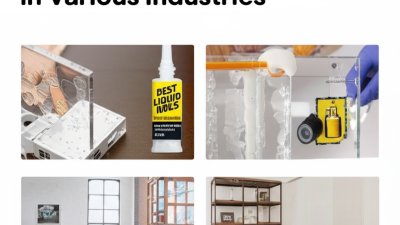

In the realm of construction and DIY projects, the importance of selecting the right Strong Construction Adhesive cannot be overstated. As noted by industry expert Dr. Rachel Thompson, a leading figure in adhesive technology, "The right adhesive can make or break the longevity and durability of your project." Understanding the nuances of different adhesive types, their applications, and performance characteristics is crucial for achieving optimal results.

A Strong Construction Adhesive is designed to create lasting bonds across a variety of materials, from wood and metal to plastics and masonry. Each project presents unique challenges, and the adhesive chosen can significantly influence both structural integrity and aesthetic appeal. Given the vast array of options available, it is essential to consider factors such as bond strength, drying time, environmental resistance, and ease of use.

Ultimately, choosing the best Strong Construction Adhesive involves more than just picking a product off the shelf; it requires a thoughtful assessment of the specific requirements of your project and a consideration of the material interactions. With expert insights and a clear understanding of your project's needs, you can confidently select the right adhesive to ensure enduring success.

When selecting the best strong construction adhesive for your projects, it's essential to understand the different types available on the market. Generally, construction adhesives can be categorized into several types, including solvent-based, water-based, and polyurethane adhesives. Solvent-based adhesives are known for their strong bonding capabilities and resistance to harsh conditions, making them ideal for exterior applications. Water-based adhesives, on the other hand, provide a safer, less toxic option suitable for indoor projects but may not offer the same strength as their solvent-based counterparts. Polyurethane adhesives are highly versatile, offering exceptional bonding strength and flexibility, which is particularly useful for projects involving a variety of materials.

Tips: When choosing an adhesive, consider the surfaces you'll be bonding. Some adhesives work better on porous materials, while others are formulated for non-porous surfaces. Always check the drying time and cure time, as this can significantly impact your project timeline.

In addition to the type of adhesive, it's crucial to assess the intended environmental conditions. If your project will be exposed to moisture or extreme temperatures, opt for an adhesive specifically designed for those conditions. Conducting a small test on scrap materials can also help ensure compatibility and bonding strength before proceeding with your main project.

When selecting the best strong construction adhesive for your projects, there are several key factors to consider to ensure optimal performance and durability. First and foremost, it's essential to identify the materials you will be working with. Different adhesives are formulated for specific surfaces, such as wood, metal, ceramic, or plastic. Understanding the compatibility of the adhesive with the materials at hand will significantly affect the strength and longevity of the bond.

Another crucial factor is the environmental conditions in which the adhesive will be used. Some adhesives are designed for indoor use, while others can withstand outdoor elements like moisture, heat, or extreme cold. Choosing an adhesive that is appropriate for the environment will prevent bond failure and enhance the longevity of your project.

**Tips:** Always check the curing time and strength rating of the adhesive before use. A faster curing time might be beneficial for quick projects, but ensure it still provides sufficient bond strength. Additionally, consider the application method; some adhesives come in tubes or syringes that allow for precise application, while others may require a brush or roller. This can impact both ease of use and the neatness of your application.

When evaluating construction adhesives, understanding their strength and durability is crucial for successful project outcomes. Strength can be determined by examining the adhesive's shear strength, tensile strength, and peel strength, which indicate how well the adhesive can hold materials together under different types of stress. For instance, projects that experience high levels of movement or stress may require adhesives with high shear strength to prevent failure. Additionally, tensile strength is important in applications where materials are pulled apart, while peel strength is crucial for layered adhesion.

Durability, on the other hand, involves assessing how well an adhesive performs over time, particularly in varying environmental conditions. Factors such as temperature fluctuations, humidity levels, and exposure to chemicals can significantly impact an adhesive's longevity. Choose adhesives specifically designed to withstand the environmental conditions of your project; for example, those with water resistance for outdoor applications, or those resistant to chemicals for industrial settings. By thoroughly evaluating both the strength and durability of adhesives, you can select the most appropriate option that will ensure the longevity and effectiveness of your construction projects.

When using construction adhesives, proper application is crucial to ensuring a strong bond. First and foremost, it is essential to prepare the surfaces that will be bonded. Both surfaces must be clean, dry, and free from any dust, grease, or paint that could interfere with adhesion. A thorough wiping with a suitable solvent can help achieve this, and in some cases, roughening the surface with sandpaper can enhance adhesion significantly by increasing the area for the adhesive to grip.

Additionally, application techniques play a pivotal role in the effectiveness of the adhesive. For best results, apply the adhesive evenly across the surface, using a trowel or a caulking gun as appropriate. It's important to follow the manufacturer's instructions regarding the thickness of the adhesive layer and the open time before the surfaces need to be brought together. Once applied, firmly press the materials together and, if possible, use clamps to maintain pressure while the adhesive cures. This ensures that the adhesive fully engages both surfaces, maximizing strength and durability. Always allow adequate curing time as specified, to achieve optimal results for your construction projects.

When working on construction projects, the use of strong adhesives is often essential for creating lasting bonds. However, safety considerations should always be at the forefront when handling these substances. It's crucial to understand the potential hazards associated with construction adhesives, which can include toxic fumes and skin irritation. Always ensure that you are working in a well-ventilated area to minimize inhalation risks and wear appropriate safety gear, such as gloves and masks, to protect against skin contact and respiratory issues.

In addition to personal safety, it's important to be aware of the storage and disposal of construction adhesives. These materials can be flammable, and improper storage may lead to hazardous situations. Make sure to keep adhesives in a cool, dry place, away from direct sunlight and heat sources. Moreover, comply with local regulations regarding disposal, as many adhesives can be classified as hazardous waste. By prioritizing safety measures and following best practices, you can significantly reduce the risks associated with using construction adhesives in your projects, fostering a safer working environment.