Inquiry

Form loading...

Choosing the right construction glue for wood can significantly affect your project. Woodworkers often overlook this crucial step. According to expert Jennifer Martinez, “The right glue makes all the difference in durability and finish.”

When selecting construction glue for wood, consider the type of project. For indoor furniture, a strong PVA glue works well. If you work with outdoor projects, waterproof options are essential. Each type of glue has its specific use. Not all glues provide the same results, which can lead to unexpected failures.

Remember, trial and error is part of the learning process. You might find that your first choice isn't the best for every project. Understanding the strengths and weaknesses of various glues will guide you. Construction glue for wood requires thoughtful consideration of your materials and their conditions.

When choosing construction glue for wood, it's important to understand the different types available. The two main categories include polyvinyl acetate (PVA) and polyurethane adhesive. PVA is often used for indoor projects and offers strong bonds. It sets quickly, usually within 30 minutes. However, it is sensitive to moisture, which can limit its outdoor use.

Polyurethane adhesive, on the other hand, is more versatile. It adheres well to various materials, including wood. Data from the Adhesive and Sealant Council shows that polyurethane provides higher water resistance. This makes it suitable for outdoor projects or areas prone to dampness. Its drying time can be longer than PVA, taking several hours to fully cure, which might frustrate those needing immediate results.

While both types are effective, consider the project requirements. The choice of glue can impact the longevity and quality of the bond. Mistakes can happen. Some might find that PVA does not hold up as expected in humid conditions. Reflection on past experiences can guide better choices. Understanding these nuances ensures a more successful outcome in your wood projects.

When choosing construction glue for wood, several factors must be considered. The type of wood can greatly influence the adhesive's performance. Softwoods like pine require different adhesives than hardwoods such as oak. According to a study by the Wood Adhesives Association, glue performance can vary by over 30% based on wood type. This emphasizes the importance of selecting the right adhesive for your specific material.

Another key factor is the environmental conditions where the glue will be used. For outdoor projects, water resistance is essential. In contrast, indoor applications may prioritize ease of cleanup. A report from the Adhesive and Sealant Council notes that moisture-resistant adhesives exhibit a 25% higher bond strength in humid conditions. Be wary of temperature fluctuations, as some glues may not perform well in extreme conditions.

It's also crucial to consider curing time. Instant adhesives may seem appealing, but they can lead to quick failures if the joint isn’t properly aligned. A study indicated that improper initial application can reduce bond strength by up to 40%. Always ensure proper joint fit and allow adequate curing time for the best results.

| Factor | Description | Importance Level |

|---|---|---|

| Type of Glue | Different types of construction glues are designed for specific applications. Choose between polyurethane, epoxy, or PVA depending on your project. | High |

| Drying Time | Consider how quickly you need the glue to set. Some glues dry in minutes, while others require hours. | Medium |

| Water Resistance | If the wood will be exposed to moisture, select a waterproof glue to ensure durability. | High |

| Ease of Use | Some glues come in user-friendly packaging with applicators, making them easier to work with. | Medium |

| Color and Finish | Choose a glue that dries clear or matches your project's finish to maintain aesthetics. | Low |

| Bond Strength | Evaluate the adhesive strength, especially for structural projects requiring strong bonds. | High |

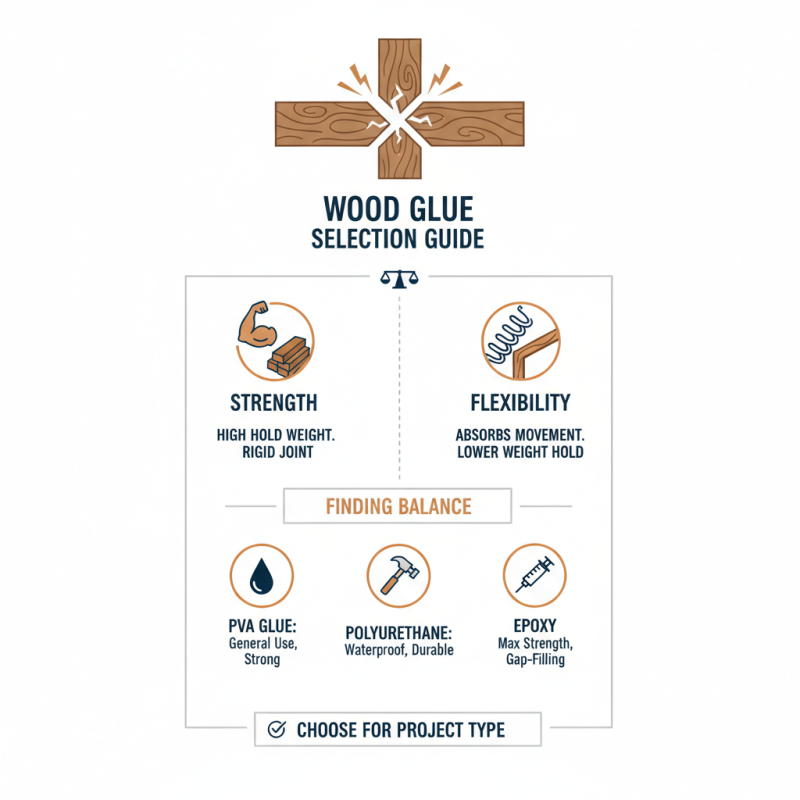

Choosing the right construction glue for wood can be challenging. Many options vary in strength and flexibility. The strength of a glue determines how much weight it can hold. Higher strength glues are often stiffer, which can limit flexibility. On the other hand, more flexible options might not hold as much weight. This is essential in woodworking. You need to find the right balance.

When comparing glues, consider the project’s purpose. For furniture, a strong bond is crucial. But, if you’re working on items that need to bend or move, flexibility becomes key. Some glues dry clear, which is great for aesthetics. Others may expand when drying, affecting your joint's appearance.

Tips: Test on scrap wood first. This helps you see how glue behaves. Always check drying times too. Some glues may seem strong initially but weaken over time. Reflect on your project too. Are you using the best glue for your needs? Understanding the pros and cons of each glue type can save time and frustration.

When applying wood glue, preparation is key. Start by ensuring both surfaces are clean and dry. Dust or grease can weaken the bond. Use sandpaper to create a rough surface; this helps the glue grip better. Don't rush—taking your time here makes a difference.

Apply the glue evenly using a brush or a roller. Too much glue can create a mess. A thin, even layer ensures a strong bond without excess oozing out.

Once the pieces are in place, clamp them tightly. Proper pressure is vital for a good bond.

Curing time varies based on the glue used. Wait patiently; early handling can break the bond. Look for any missed spots and touch them up if needed. If it’s not perfect the first time, don’t be discouraged. Each project teaches new lessons for next time.

Proper storage of construction glue is vital for ensuring its performance. Most adhesives have a shelf life, often around 1 to 2 years when stored correctly. According to a report by the Adhesive and Sealant Council, nearly 30% of construction failures stem from improper adhesive use. Therefore, keeping the glue in a cool, dry place can prevent premature aging. Exposure to extreme temperatures or humidity can alter the properties of the glue, leading to weaker bonds.

When using construction glue, optimal temperature ranges are crucial. Many products perform best at temperatures between 50°F and 90°F. An industry study indicated that using glue outside of this range can reduce adhesion strength by up to 50%. It's also important to check the expiration date. Using expired glue may lead to unexpected results. Ensure that the cap is tightly sealed after each use to minimize moisture exposure.

It's essential to clean surfaces thoroughly before application. Dirt and grease can interfere with the bonding process. A survey showed that 40% of DIY enthusiasts overlook surface preparation. This negligence often results in the need for rework. Users should also shake or stir the glue as instructed, allowing for a uniform consistency. Being mindful of these details can make all the difference in the outcome of your wood projects.