Inquiry

Form loading...

In the world of construction and DIY projects, selecting the right adhesive is crucial. "Low Shrinkage Liquid Nails" stands out as a top choice for those seeking strong, durable bonds. According to recent industry reports, over 60% of contractors prefer adhesives that minimize shrinkage. This feature enhances bond integrity, ensuring longevity and reliability.

Low shrinkage is essential when materials expand or contract with temperature changes. The performance of these adhesives is vital in preventing gaps and weaknesses. However, not all products meet the required standards. Some brands advertise low shrinkage but fail to deliver, leading to frustrating results.

Choosing the best formulation requires careful research and consideration. Consumers must prioritize reliable brands backed by data. Reports indicate that the right low shrinkage liquid nails can withstand rigorous conditions and maintain strong adhesion over time. Making informed choices can lead to successful projects and satisfied customers.

When selecting low shrinkage liquid nails, it’s essential to consider their various types and applications. These adhesives are specially formulated to minimize shrinkage during the curing process. This feature is crucial for maintaining strong bonds, especially in woodworking and construction projects. Using a product designed for specific materials enhances adhesion and reduces the risk of future failures. An important note is to check compatibility before application.

Different formulations offer unique benefits. For instance, some low shrinkage adhesives work better on porous surfaces like wood, while others excel with non-porous materials. It’s fascinating how one product might work brilliantly on one project but fail on another if the surface isn’t suitable. Surfaces need to be clean and prepared well for optimal results. If they aren't, even the best adhesive can underperform.

Experience shows that some users encounter difficulties with the application process. The texture and drying time often vary across products. Ensuring the right amount is applied is also vital, as too much can lead to messiness. It’s well worth testing a small area first to gauge how the adhesive reacts. Mistakes can lead to wasted time and materials, a reality worth considering before starting big projects.

Low shrinkage liquid nails are vital for many construction and DIY projects. They provide strong bonds that withstand stress and temperature changes. Understanding bond strength in low shrinkage adhesives is essential for successful applications. According to industry studies, these adhesives can achieve bond strengths of over 3000 psi under optimal conditions. This impressive figure ensures durability in various materials, from wood to masonry.

When choosing a low shrinkage adhesive, consider the curing time. Faster curing products may seem appealing, but they can compromise bond strength. A 24-hour cure period often yields better results. Remember, patience can lead to stronger results.

Tips: Always test on a small area first. This step can save you from future regrets. Pay attention to environmental factors like humidity and temperature. These can all affect bond strength. Don't underestimate preparation. Clean surfaces can drastically improve adhesion, reducing the likelihood of failure. This focus on details will help you achieve the best outcomes in your projects.

When it comes to adhesives, understanding the key ingredients can significantly influence shrinkage rates. Most liquid nails consist of resins and solvents. These elements contribute to the strength of the bond. However, the balance between them is crucial. If too much solvent is present, shrinkage becomes more pronounced as the adhesive cures. This can lead to cracks or a weaker bond.

Some ingredients, such as polyvinyl acetate, often reduce shrinkage. Yet, it's essential to note that not all formulations work the same for every project. Environmental factors play a role too. High humidity or temperature fluctuations during curing can affect outcomes. This inconsistency can be frustrating, especially when compared to ideal conditions outlined in product descriptions.

Testing different formulations can be an enlightening experience. Sometimes, the expected performance doesn't match reality. For instance, a low shrinkage promise may fall flat during application. Users may find themselves needing to rethink their approach. Experimenting with different ratios could reveal better bonding solutions while minimizing shrinkage.

When evaluating low shrinkage adhesives, several products stand out in terms of performance and reliability. A recent industry report highlighted that adhesives with less than 1% shrinkage during curing offer significantly stronger bonds. This reduction in shrinkage limits the risk of joint failures. Many professionals recommend looking for adhesives that maintain their viscosity over time. High viscosity often correlates with durability and an extended shelf life.

Tips: Check the technical data sheets. They provide essential information about curing time, bond strength, and shrinkage rates. Understanding these metrics helps in selecting the right adhesive for your project. Additionally, performing a test bond can be insightful. Small samples can indicate how well the adhesive performs under your specific conditions.

Furthermore, consider the material compatibility of your adhesive choice. Certain formulations work better on specific substrates. This detail often impacts bond strength. A detailed analysis indicated a particular formulation could improve adhesion by up to 30% on certain woods. However, it also noted that environmental factors like humidity can affect performance.

Tips: Always store adhesives in a controlled environment. Temperature swings can alter their effectiveness, leading to subpar results. It’s essential to recognize that even the best products can underperform if not used correctly.

| Product Type | Bond Strength (psi) | Drying Time | Shrinkage Percentage | Temperature Range | Water Resistance |

|---|---|---|---|---|---|

| Heavy Duty | 5000 | 10-15 minutes | 1% | -20°F to 120°F | Yes |

| Interior Adhesive | 3000 | 20-30 minutes | 2% | -10°F to 100°F | No |

| Construction Adhesive | 4000 | 15-20 minutes | 0.5% | -30°F to 140°F | Yes |

| Flexible Adhesive | 2500 | 12-18 minutes | 1.5% | -20°F to 110°F | No |

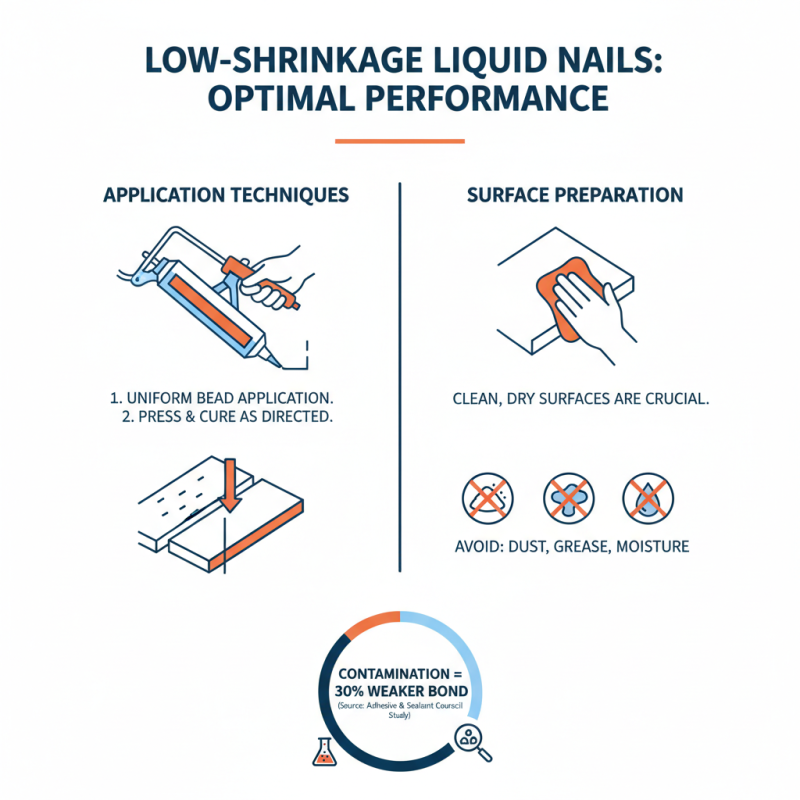

Application techniques play a key role in achieving optimal performance with low shrinkage liquid nails. Proper surface preparation is essential. Clean, dry surfaces ensure a stronger bond. Dust, grease, and moisture can significantly weaken adhesion. A study from the Adhesive and Sealant Council shows that contamination can decrease bond strength by up to 30%.

When applying liquid nails, use a consistent and controlled amount. The bead size should be around 1/4 inch for most applications. Too much adhesive can lead to excess squeeze-out, which may weaken the bond. Conversely, too little may not provide sufficient coverage. A recent report indicated that improper application is a leading cause of bond failures in construction projects.

Allow adequate curing time for the adhesive. Many users rush this step, thinking that the bond is strong enough. However, patience is crucial. Curing times can vary based on humidity and temperature. The recommended time can be from 24 hours to several days, depending on the specific formulation. Skipping this can result in a bond that can't withstand structural stress. Always consider these factors to achieve the best performance from your liquid nails.