Inquiry

Form loading...

In 2026, choosing the best glue for FRP panels is essential for construction and renovation projects. The demand for fiberglass reinforced plastic (FRP) panels is rising. According to a recent industry report, the global FRP market is expected to reach $23 billion by 2026. This growth means that selecting the right adhesive is more crucial than ever.

Understanding the properties of glue for FRP panels is vital. Not all adhesives offer the same performance. Some may not withstand high humidity or extreme temperatures. Inadequate adhesives can lead to panel degradation and costly repairs. Industry experts recommend glues specifically designed for FRP applications. These products ensure a strong bond while withstanding environmental stressors.

While many options are available, the choice isn't always straightforward. Each project has unique requirements. Factors like panel thickness, surface texture, and installation environment matter. Reflecting on these elements will lead to better results. Ultimately, the right glue for FRP panels can make a significant difference in longevity and aesthetics. Choices made now will impact future maintenance and overall project success.

FRP panels, or Fiber Reinforced Plastic panels, are increasingly popular in various industries. Their lightweight yet durable nature makes them ideal for both construction and design. These panels resist moisture, chemicals, and UV rays, which contributes to their longevity. FRP is often used in applications ranging from wall coverings to industrial storage tanks. Understanding their properties helps in choosing the right adhesive for your projects.

Tips: When working with FRP, ensure proper surface preparation. Clean the area thoroughly to maximize adhesion. Also, consider the environmental conditions. Humidity and temperature can affect glue performance.

The installation process often requires precision. Align the panels carefully before applying adhesive. Mistakes can lead to misalignment, which may weaken the bond. If the glue doesn’t set properly, it could lead to costly repairs later. Always test the adhesive on a small section first to check compatibility. It’s a small step, but one that could save time and materials.

When selecting adhesives for FRP (Fiber Reinforced Polymer) panels, key properties are essential. These panels are often used in construction, automotive, and marine applications due to their lightweight and high-strength characteristics. According to recent reports from the Adhesive and Sealant Council, strong adhesion to FRP requires products that offer excellent chemical resistance and durability.

Adhesives with a flexible bond will help absorb shocks and impacts, making them ideal for environments that experience temperature fluctuations. A study showed that formulations that can withstand continuous service temperatures of up to 200°F outperform others in extreme conditions. This flexibility often leads to better performance, but it can also present challenges in ensuring a reliable setup.

Furthermore, the curing time of the adhesive is crucial. Quick-setting options are beneficial but may compromise bond strength. On the other hand, longer curing times can enhance the bond but may slow down project timelines. It often leads to a trade-off that needs careful consideration. Ultimately, the right adhesive is one that meets the specific demands of your FRP application while considering environmental factors and expected stress.

| Adhesive Type | Strength (psi) | Cure Time | Temperature Resistance (°F) | Water Resistance | Flexibility |

|---|---|---|---|---|---|

| Epoxy | 3500 | 24 hours | 200 | Excellent | Rigid |

| Polyurethane | 2500 | 12 hours | 180 | Good | Flexible |

| Acrylic | 2000 | 1 hour | 150 | Moderate | Semi-flexible |

| Silicone | 1000 | 48 hours | 300 | Excellent | Highly flexible |

When selecting the right glue for FRP panels in 2026, several key factors come into play. Good adhesive must endure temperature shifts. It should also resist moisture and UV exposure. Many top brands focus on these essentials, but not all meet expectations consistently. Some products claim to offer durability, yet they fail when tested over time.

In this space, there are noticeable differences among leading brands. Some adhesives excel in strength but are hard to apply. Others spread easily but lose their grip. It’s crucial to consider what matters most for your project. Application ease versus long-term performance often leads to tough choices.

User reviews may highlight these inconsistencies. A product that shines in demos might not fare well in everyday settings. It’s wise to gather feedback from diverse sources. Not all solutions fit every scenario, and trial and error are often necessary. You might find an ideal match with some patience and research.

This chart displays the adhesive strength of different glue types suitable for FRP panels in 2026. The values represent the maximum adhesive strength measured in megapascals (MPa).

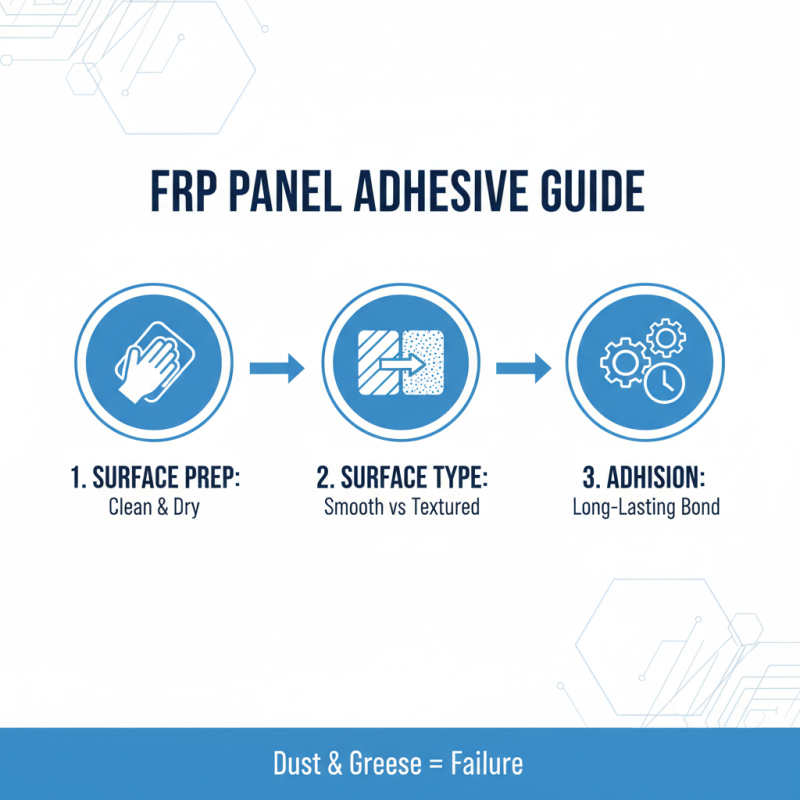

When applying adhesives for FRP panels, surface preparation is crucial. Begin by cleaning the surfaces thoroughly. Remove any dust, grease, or contaminants. Use a suitable cleaner for the material. A rough surface can enhance adhesion, so consider light sanding. This step may feel tedious, yet it significantly impacts the bond strength.

Next, apply the adhesive evenly. Use a notched trowel for a proper spread. This ensures that the adhesive covers all areas. Pay attention to corners and edges, as they often fail first. Allow for adequate open time based on the adhesive's instructions. Sometimes, the waiting period is longer than expected. Patience here can yield better results.

Once the panels are in place, apply pressure. This step is often overlooked. Use weights or clamps, ensuring an even bond across the surface. Monitor for any leaks of adhesive during this time. It’s important to adjust if you notice any misalignment. Even the best-prepared surfaces can have hiccups. Continuously checking the bond during curing is a wise approach.

When choosing the right glue for FRP panels, several factors come into play. The type of surface is crucial. Smooth surfaces may require different adhesives than textured ones. A thorough surface preparation is essential. Dust and grease can compromise adhesion and lead to failure over time.

The environmental conditions also matter. High temperatures or humidity can affect the glue's performance. Ensure the adhesive you select is suitable for these conditions. Not all glues are designed for every application. Some may set too quickly, while others might take too long, which can lead to misalignment.

Finally, consider the adhesion strength necessary for your project. If the panels will face heavy loads or stresses, a stronger adhesive is vital. Testing different glues on a sample piece can provide insight into their effectiveness. This trial-and-error process can be messy, but it is necessary for the best results. Failure to choose wisely may lead to costly repairs.