Inquiry

Form loading...

In the world of construction, choosing the right adhesive is critical for quality and durability. Construction glue plays a vital role in ensuring strong and lasting bonds between materials. According to a report by the Adhesive and Sealant Council, the construction adhesive market has grown by over 5% annually in the past five years. This rising trend highlights the increasing demand for reliable bonding solutions.

Expert Tom Richards, a leading figure in the adhesive industry, emphasizes, "A strong bond can make or break a project's success." This statement underlines the significance of selecting the appropriate construction glue for various applications. With the variety of options available, contractors must navigate through products that differ in strength, drying times, and compatibility with materials.

Despite the advancements in glue technology, challenges remain. Some users still experience failures in bond integrity. This often stems from improper application techniques or adverse environmental conditions. Reflecting on these issues helps us recognize the need for continuous education and training in adhesive use. A strong bond is more than just the right product; it involves knowledge and attention to detail.

When choosing the right construction glue, it's vital to understand your materials. Different types of glue work better with specific surfaces. For example, wood requires a different adhesive than metal. Some glues create a strong bond for porous materials, while others excel with non-porous surfaces. Knowing this is essential to achieving a lasting bond.

Polyurethane glue is versatile and ideal for wood-to-wood bonding. It expands as it cures, filling gaps effectively. However, it can be messy. Cleanup is often more challenging with this option. Epoxy, on the other hand, is great for metal and ceramic. It provides a strong hold but takes longer to set. If rushed, one may face issues with alignment.

Construction adhesives have their limits. They can't always withstand water exposure or extreme temperatures. It’s important to test a small area first. Sometimes, the results may not meet expectations. Each material reacts differently, even with the right glue. Take your time to select the best adhesive for your project.

When selecting construction glue, several essential factors come into play. One critical aspect is the material compatibility. Different adhesives work best with specific substances, such as wood, metal, or plastic. According to industry reports, nearly 70% of adhesive failures stem from poor material selection. Ensuring the glue is designed for your specific materials will greatly enhance bonding strength.

Another factor is the curing time. Some projects require immediate hold, while others allow for longer setting times. A study published in the Journal of Adhesion Science revealed that bonds strengthen significantly with appropriate curing conditions. Be sure to read the glue's instructions. Incorrect application can lead to weak links. Surface preparation cannot be overlooked, either. Clean, dry surfaces promote better adhesion.

It's also vital to consider environmental factors. Exposure to moisture, heat, or chemicals can weaken bonds. A report from the Adhesive and Sealant Council indicates that 40% of construction failures are related to environmental stress. Evaluate your project's conditions and choose a glue that withstands these challenges. Always reflect on past experiences with adhesives. What worked, and what didn't? Learning from these scenarios can prevent future mistakes.

| Glue Type | Best Use Case | Drying Time | Strength | Water Resistance |

|---|---|---|---|---|

| Polyurethane Glue | Wood to Wood, Outdoor Use | 24 hours | High | Yes |

| Epoxy Adhesive | Metal, Glass, Ceramics | 5 to 30 minutes | Very High | Yes |

| PVA Glue | Paper, Cardboard, Wood | 30 minutes | Medium | No |

| CA Glue (Super Glue) | Quick Repairs, Small Parts | Seconds | High | No |

| Construction Adhesive | Subfloor, Paneling | 24 hours | High | Yes |

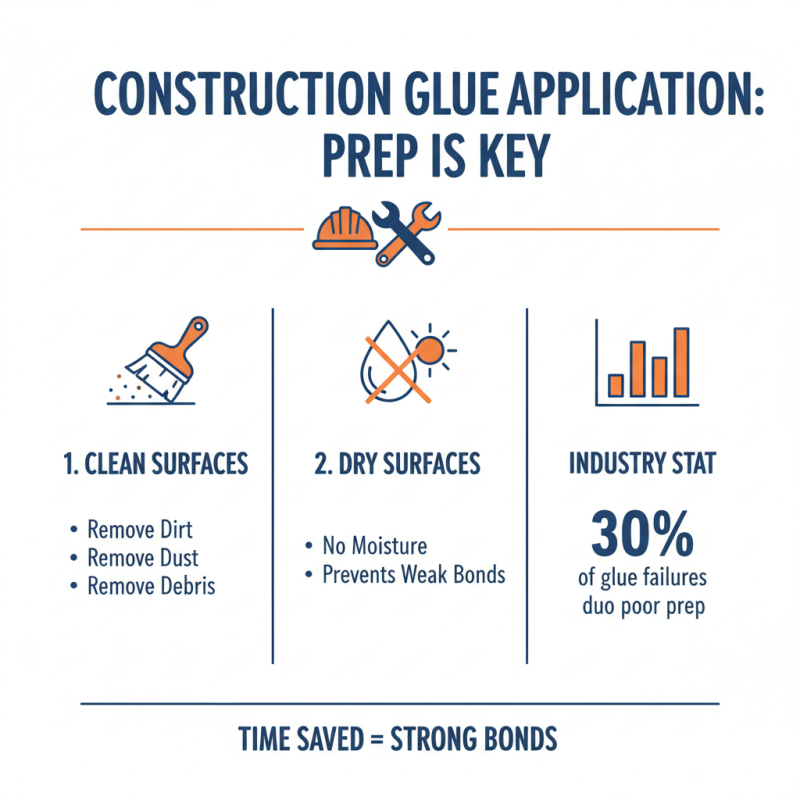

When applying construction glue, preparation is essential. Ensure surfaces are clean and dry. Dirt, dust, or moisture can weaken the bond. According to a recent industry survey, nearly 30% of construction glue failures stem from inadequate surface preparation. This statistic highlights the importance of taking time to prepare.

Next, apply the glue evenly. Uneven application can lead to weak spots. Use a caulking gun for a consistent bead. Over-application may cause the glue to ooze out, which can disrupt the alignment of materials. Aim for a thin layer, as more glue does not always mean a stronger bond. Studies suggest that excess glue might take longer to cure, increasing the risk of imperfections.

After the glue is applied, clamp the materials together. This pressure helps create a strong bond. However, over-clamping can lead to unwanted shifts. A balance is crucial. Monitor the curing process closely. Environmental factors like temperature and humidity can affect the glue's performance significantly. Some projects may fail because these elements were not considered.

When working with construction glue, achieving strong, long-lasting bonds is crucial. According to industry studies, properly prepared surfaces can enhance adhesive performance by up to 80%. This means that ensuring clean, dry surfaces before application is vital. Dust, oil, or moisture can significantly weaken the bond.

Tip: Always clean and dry surfaces before applying glue. A simple wipe with a cloth may not be enough. Rely on solvents for stubborn residues.

Temperature also plays a key role. Most construction adhesives perform best in moderate temperatures. Extreme cold or heat can alter their properties. A study by the Adhesive and Sealant Council found that certain adhesives lose up to 50% of their strength at inappropriate temperatures.

Tip: Check product specifications for temperature ranges. Working in an optimal environment can save time and materials.

Lastly, patience is essential. Many adhesives require curing time. Rushing can lead to premature failure. In construction, a small oversight can turn into costly repairs later. Even experienced builders sometimes overlook this step.

Using construction glue can be tricky. One common mistake is applying it to dirty or dusty surfaces. Clean the surfaces before you start. Even a small amount of debris can weaken the bond. Also, don’t rush. Give the glue enough time to set properly.

Another pitfall is using too much glue. Many people think it will create a stronger bond, but that’s not true. A thin, even layer is often more effective. Too much can lead to drips and mess. Let it cure fully. Patience is key.

Finally, using the wrong type of glue for your project can lead to disaster. It's essential to read the label. If you're not sure, ask for advice. Different materials may require specific adhesives. Knowing what works best can save time and effort. Mistakes can happen. Learn from them to improve your next project.