Inquiry

Form loading...

When it comes to construction projects, the right materials can make a significant difference. One essential component is the Construction Epoxy Adhesive. This powerful adhesive ensures durability and reliability in bonding various materials. Whether you are dealing with wood, concrete, or metal, a good epoxy can provide solid results.

Choosing the best Construction Epoxy Adhesive isn't straightforward. Many options are available, each with unique features and benefits. Some might find themselves overwhelmed by the choices. It's crucial to consider various factors, such as curing time and temperature resistance. Each project might require a different type of adhesive, which can lead to confusion.

Additionally, one must reflect on the environmental impact of epoxy adhesives. Some adhesives contain harmful chemicals. Understanding these impacts is vital for responsible usage. In this guide, we explore the top options available in 2026. We aim to simplify the decision-making process, providing insights that can lead to better choices.

When choosing construction epoxy adhesives, several factors play a crucial role. The formulation of the adhesive is essential. Some epoxies are designed for specific materials, while others offer versatility. For instance, a study by the Adhesive and Sealant Council reports that epoxy adhesives can achieve bond strengths of up to 3,600 psi, depending on material compatibility.

The curing time is another key consideration. Fast-curing adhesives can be convenient for quick repairs, but they may not penetrate as deeply, affecting durability. According to industry reports, a longer curing time often leads to stronger bonds. However, this comes with the trade-off of longer waiting periods before the adhesive can handle stress.

Environmental factors also need attention. Temperature and humidity can impact the performance of epoxy adhesives. An adhesive performing well in one environment might fail in another. For example, high humidity can affect curing. Therefore, testing in real conditions is necessary. Understanding these variables can help avoid failures and ensure that your construction projects succeed.

When choosing epoxy adhesives for construction, it's essential to understand the types available. Common types include solid epoxy, flexible epoxy, and low-viscosity epoxy. Each type serves specific needs based on application. Solid epoxy is known for its strength. It can withstand heavy loads and harsh environments. Flexible epoxy, on the other hand, provides better flexibility. This is crucial in areas where movement occurs, such as joints and connections.

According to a recent industry report, around 60% of construction professionals prefer low-viscosity epoxies for intricate applications. This type can penetrate small gaps effectively. It is ideal for bonding porous materials. However, using low-viscosity epoxy can pose challenges. It sometimes leads to messy applications, resulting in excess adhesive around the bonded surface. Precision is key here.

Not all projects require the same epoxy. Some may need a quick cure time, while others benefit from a longer open time. Reports suggest that 45% of users find balancing these needs a constant struggle. Additionally, the environmental conditions during application can affect the performance of the adhesive. Thus, it's essential to evaluate these factors carefully.

This chart displays the performance ratings of various construction epoxy adhesives across different criteria including strength, durability, cure time, water resistance, and UV stability. The ratings are on a scale of 0 to 100, providing a clear overview of their effectiveness in construction applications.

When it comes to construction epoxy adhesives, several top brands stand out in 2026. These products are known for their strength and versatility. Users often choose adhesives for projects ranging from simple repairs to complex builds. The best epoxy adhesives provide a reliable bond for a variety of materials, including metal, wood, and concrete.

Tips for selecting the right epoxy adhesive include considering the environment where it will be used. Temperature and humidity levels can affect curing time and bond strength. Ensure that the surface is clean and dry before applying the adhesive. You might find that some products require specific mixing techniques for optimal results. Not all epoxies are created equal; some may not work well with certain materials.

Always test a small area first. This can save you time and prevent mistakes. Be aware of the workability period; some adhesives set quickly and leave little room for adjustments. Learning from past experiences can help you choose the right product for future projects. It’s okay to experiment with different options, as this is part of the process.

When choosing the right construction epoxy adhesive, it's essential to focus on strength, durability, and set times. Strength determines how well the adhesive bonds materials. For instance, some epoxies provide a tensile strength of over 3000 PSI, making them suitable for heavy-duty projects. However, not all products perform equally. Testing is crucial to understand which options can handle your specific needs.

Durability is equally important. A strong bond may weaken over time if the adhesive doesn’t withstand environmental factors. Some epoxies can resist extreme temperatures and moisture, while others may crack or degrade. A perfect adhesive for indoor use may not perform well outdoors. This inconsistency leads to frustrating outcomes.

Set times can vary, too. Some adhesives cure in under an hour, while others may take 24 hours. Quick-setting options are great for rushing jobs, but they may not offer the strength needed for every situation. Patience can lead to better results, yet many rush through projects. Reflecting on these factors is essential for success. Quality tests and trials can prevent costly mistakes. Understanding each adhesive's unique properties puts users in control of their projects.

| Adhesive Type | Strength (psi) | Durability (Years) | Set Time (Hours) | Temperature Resistance (°F) |

|---|---|---|---|---|

| Standard Epoxy | 3500 | 5 | 24 | 150 |

| Fast-Setting Epoxy | 3000 | 4 | 1 | 160 |

| High-Temperature Epoxy | 4000 | 7 | 48 | 250 |

| Marine Epoxy | 3200 | 6 | 12 | 180 |

| Structural Epoxy | 5000 | 10 | 24 | 200 |

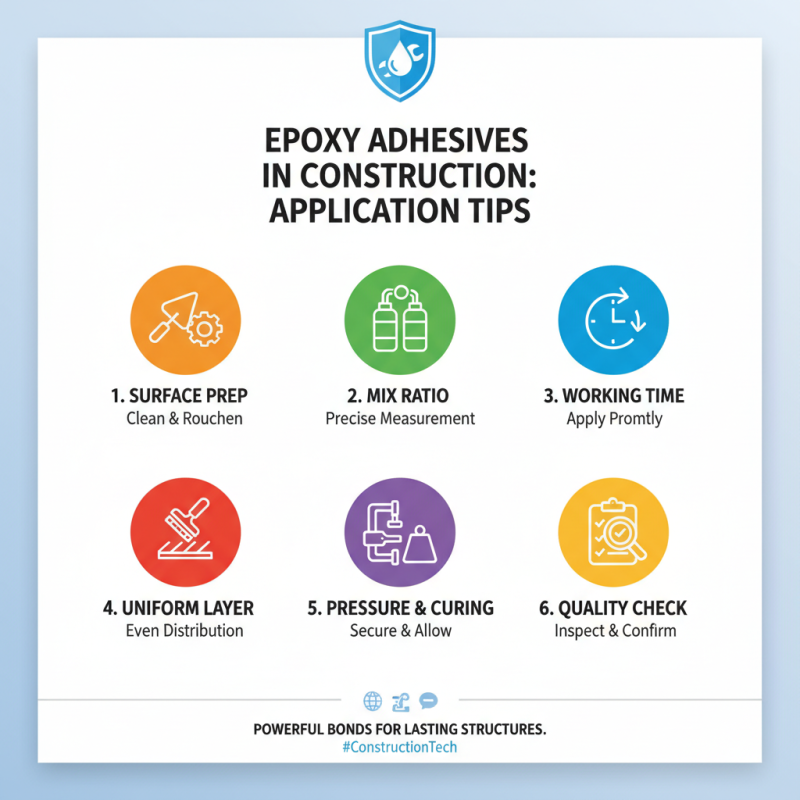

Epoxy adhesives are powerful tools for construction. Proper application is crucial for achieving the best results. Here are some tips to consider.

Preparation is essential. Clean the surfaces thoroughly before applying epoxy. Dust, grease, or moisture can weaken the bond. A rough surface also helps to enhance adhesion. Use sandpaper or a wire brush to provide texture. Working in a well-ventilated area is vital for safety and effectiveness.

When mixing epoxy, follow the instructions carefully. Measure the components accurately. Improper ratios can lead to failure. Apply the mixture evenly to avoid uneven curing. Don't rush. Allow sufficient curing time before stressing the bond. Patience can make a significant difference.

Always keep a backup plan. Mistakes happen. If something goes wrong, assess the situation calmly. Remnants of failed attempts can linger, affecting future work. Test small areas first to ensure compatibility. Keep tools close for quick adjustments. This preparation can save time and frustration later.