Inquiry

Form loading...

High Temperature Silicone Sealant is a versatile material frequently used in various projects. Its unique properties make it suitable for high-stress environments. Choosing the right sealant often confuses many. However, understanding its advantages can simplify your decision.

One key benefit of High Temperature Silicone Sealant is its ability to withstand extreme conditions. It performs remarkably well in temperatures up to 500°F. This feature makes it ideal for applications in kitchens and industrial settings. The durability it offers is impressive but sometimes overlooked.

Using High Temperature Silicone Sealant also ensures a strong bond. This bond resists not only heat but also moisture and chemicals. While it is effective, proper application techniques are crucial. Even the best products can fail without careful use. Remember, a little practice can lead to better results and fewer mistakes.

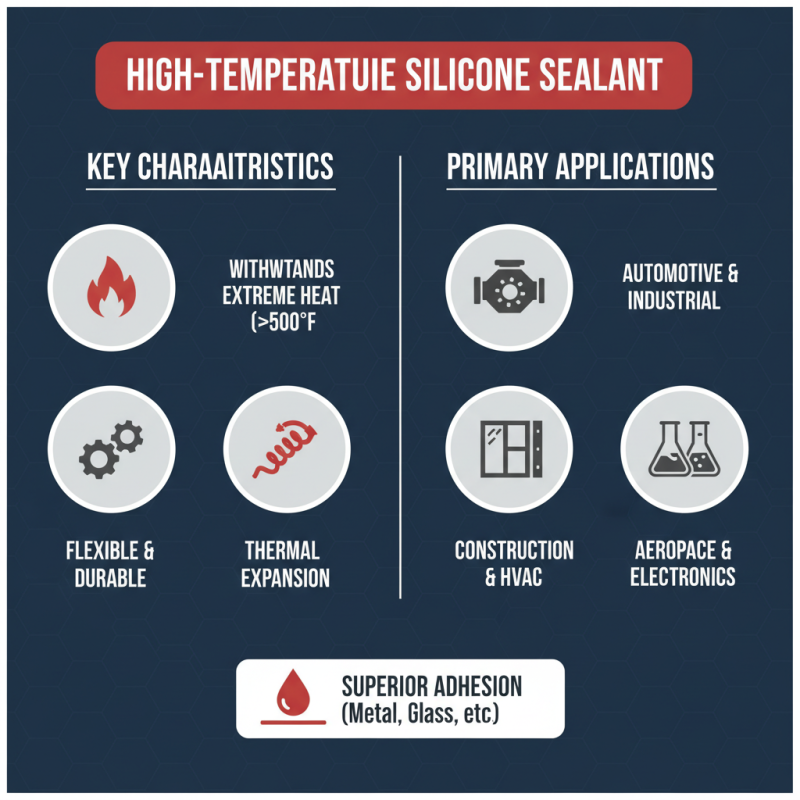

High temperature silicone sealant offers unique characteristics that make it indispensable for various applications. This type of sealant can withstand extreme temperatures, often exceeding 500°F. It maintains its flexibility and durability in harsh environments. Many projects require a material that can handle thermal expansion without cracking. High temperature silicone excels in this area. It also adheres well to many surfaces, including metal and glass. This versatility broadens its usability in different fields.

Another notable feature is its resistance to chemicals and moisture. Projects involving automotive or industrial settings often expose materials to various substances. High temperature silicone does not degrade easily in these conditions. This resilience ensures long-lasting seals that won't fail over time. Some may notice that this sealant can be tricky to apply. It can be messy if not handled properly. Consider practicing on scrap materials first for better results. Proper application requires attention to detail to ensure effectiveness.

High temperature silicone sealant is widely used in various industries for its durability and versatility. In automotive applications, it can withstand high heat from engines. This makes it ideal for sealing components such as exhaust systems and gaskets. Its resistance to extreme conditions helps ensure long-lasting performance.

In the aerospace sector, high temperature silicone sealant is crucial. It protects against harsh environments and intense thermal exposure. Aircraft parts benefit from the sealant’s flexibility and temperature resilience, enhancing safety and efficiency. However, users often overlook the importance of surface preparation. Neglecting this step can lead to poor adhesion.

For the electronics industry, this sealant is used in devices exposed to high heat. It fills gaps and prevents moisture intrusion. This function is critical in ensuring device longevity. A common mistake is applying too much sealant, which can create mess and lead to failure.

Tips for application include cleaning surfaces thoroughly before sealing. Ensure proper curing time is followed, as this affects performance. Always apply in a well-ventilated area to avoid inhalation of fumes. Careful application can make a significant difference in the quality of your project.

This chart illustrates the top 10 benefits of using high temperature silicone sealant in various projects. Each benefit is rated on a scale from 1 to 10, displaying their significance in applications across multiple industries.

High temperature silicone sealant offers remarkable durability and longevity. According to recent industry reports, these sealants can withstand temperatures ranging from -75°F to 500°F. This resilience makes them ideal for extreme conditions. They perform well in automotive, industrial, and aerospace applications, where thermal fluctuations are common.

Moreover, high temperature silicone sealants resist degradation over time. In laboratory tests, some formulations showed over 80% of their original strength even after prolonged exposure to heat. This is noteworthy for anyone managing long-term projects. However, it’s essential to choose the right type for specific applications. Not all silicone is created equal.

Applying high temperature silicone requires precision. Proper surface preparation is crucial for a strong bond. Inadequate cleaning can lead to adhesion failures. Some users reported issues when rushing this step. It's a reminder that quality work takes time. While the benefits are clear, attention to detail is sometimes lacking in practice. Consider these aspects carefully before using high temperature silicone sealants in your projects.

High temperature silicone sealant can be a budget-friendly choice for various projects. Its longevity and durability make it a cost-effective solution. This sealant withstands extreme temperatures, reducing the need for frequent replacements. In the long run, it saves both time and money.

When budgeting, consider both the initial cost and the potential savings. You may pay more upfront, but fewer repairs can lead to lower overall costs. Allocate funds efficiently to ensure quality materials. This investment can enhance the project’s longevity.

Tips: Always test a small area first. Check how the sealant reacts to high heat. Adjust your application process based on this feedback. Provide adequate drying time to maximize effectiveness. Make sure you have enough product to avoid extra trips to the store, which can add costs.

High temperature silicone sealant offers several environmental and safety advantages. Many formulations contain minimal volatile organic compounds (VOCs). This means lower air pollution. It is essential for indoor applications where air quality matters. By reducing harmful emissions, these sealants contribute to healthier living spaces.

When using high temperature silicone sealants, safety is paramount. Proper ventilation is necessary during application. This reduces the risk of inhalation exposure. Some might overlook this step, thinking it’s insignificant. However, even minor oversights can lead to health issues. Wearing gloves and masks is crucial. These simple precautions can prevent skin irritation and respiratory problems.

In terms of disposal, it’s vital to follow local guidelines. Many people discard silicone materials carelessly. That might create environmental hazards. Proper disposal methods should include recycling where possible. There’s always room for improving how we handle materials. Reflecting on these practices can lead to better environmental stewardship.

| Benefit | Description | Environmental Considerations | Safety Considerations |

|---|---|---|---|

| High Temperature Resistance | Can withstand extreme temperatures, maintaining integrity and adhesion. | Made from materials that minimize environmental impact. | Non-toxic when cured, safe for residential use. |

| Flexibility | Remains flexible, allowing for expansion and contraction. | Low volatility during application reduces air pollutants. | Minimal irritation to skin and eyes; use with care. |

| Durability | Highly resistant to weathering and aging, ensuring long-term performance. | Recyclable options available for sustainable practices. | Follow safety guidelines for application to avoid hazards. |

| Adhesion | Strong bonding capabilities with various materials. | Low environmental toxicity compared to some adhesives. | Ensure good ventilation during application. |

| Chemical Resistance | Resists oils, solvents, and harsh chemicals. | Product formulations may vary; check for eco-friendly versions. | Use protective gear to minimize exposure to chemicals. |

| Water Resistance | Excellent moisture sealing capabilities for wet environments. | Water-based or low VOC options available. | Safe for use in kitchens and bathrooms when applied correctly. |

| Ease of Application | User-friendly packaging and application methods. | Reduce waste with easy clean-up formulations. | Follow safety instructions for best practice during application. |

| Aesthetic Versatility | Available in various colors to match project needs. | Use products that meet colorant regulations for the environment. | Non-fuming during curing process enhances safety. |

| Cost-Effective | Long-lasting performance reduces maintenance costs. | Opt for brands that prioritize eco-friendly ingredients. | Safety datasheets available for informed usage. |