Inquiry

Form loading...

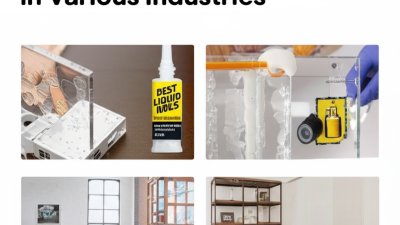

In recent years, the versatility and resilience of High-Temperature Silicone Sealant have garnered significant attention across various modern industries. This advanced material is designed to withstand extreme heat and environmental challenges, making it an ideal choice for applications ranging from automotive to aerospace and construction. The unique composition of High-Temperature Silicone Sealant not only provides exceptional durability and flexibility but also ensures a reliable seal in demanding conditions.

As industries continue to innovate and push the boundaries of technology, understanding the benefits and applications of this sealant is crucial. This exploration highlights how High-Temperature Silicone Sealant contributes to efficiency, longevity, and safety, solidifying its status as an essential material in contemporary manufacturing processes. By delving into specific use cases and advantages, we aim to illuminate the transformative potential that High-Temperature Silicone Sealant offers to modern industrial applications.

High-temperature silicone sealants play a pivotal role in aerospace applications, where their ability to withstand extreme conditions is essential. According to a report by MarketsandMarkets, the aerospace sealants market is projected to grow to $1.3 billion by 2025, driven largely by innovations in high-performance materials. These silicone sealants can endure temperatures up to 350°C (662°F), making them ideal for sealing components in engines and exhaust systems where thermal stress is unavoidable. Additionally, their excellent adhesion properties ensure a reliable bond, contributing to safety and efficiency in flight operations.

**Tips**: When selecting a high-temperature silicone sealant for aerospace applications, consider factors such as temperature resistance, adhesion strength, and cure time. It’s also crucial to verify that the sealant meets industry-specific certifications, such as AMS 3270, which is commonly required in aerospace manufacturing.

Furthermore, high-temperature silicone sealants are resistant to harsh chemicals and UV radiation, critical for maintaining the integrity of aerospace components exposed to various environmental conditions. The increasing advancements in these materials promise enhanced durability and performance, making them indispensable in modern aerospace engineering. Adopting such innovative solutions can significantly improve the longevity and safety of aircraft, reflecting the industry's commitment to excellence and reliability.

**Tips**: Implement regular inspections and maintenance to ensure that the sealants are performing optimally, and address any signs of wear promptly to uphold safety standards.

High-temperature silicone sealants are designed to withstand extreme thermal conditions, making them indispensable in various modern industries, including automotive, aerospace, and manufacturing.

These sealants exhibit remarkable thermal stability, maintaining their integrity and performance even when exposed to temperatures exceeding 500°F (260°C). This ability to resist degradation ensures that applications requiring high heat exposure, such as engine gaskets or exhaust systems, remain secure and reliable over time.

Additionally, the flexibility of high-temperature silicone sealant allows for effective sealing in environments with fluctuating temperatures. As metals expand and contract under heat, these silicone products adapt without cracking or losing adhesion.

This characteristic not only prolongs the life of the sealed components but also enhances overall operational safety. Industries benefit from reduced downtime and maintenance costs, as the sealants provide durable solutions that withstand the rigors of extreme environments, thereby boosting efficiency and performance across various applications.

High-temperature silicone sealants have emerged as indispensable materials in modern industries, particularly when compared to traditional sealants. Unlike conventional options, which often fail to maintain their integrity under extreme conditions, high-temperature silicone can endure temperatures up to 300°C (572°F) or higher. According to a recent report by the American Society for Testing and Materials (ASTM), high-temperature silicone formulations reduce downtime and maintenance costs by up to 30% in industrial applications. This remarkable temperature resistance makes it ideal for automotive, aerospace, and manufacturing applications where heat exposure is a constant challenge.

High-temperature silicone sealants have emerged as indispensable materials in modern industries, particularly when compared to traditional sealants. Unlike conventional options, which often fail to maintain their integrity under extreme conditions, high-temperature silicone can endure temperatures up to 300°C (572°F) or higher. According to a recent report by the American Society for Testing and Materials (ASTM), high-temperature silicone formulations reduce downtime and maintenance costs by up to 30% in industrial applications. This remarkable temperature resistance makes it ideal for automotive, aerospace, and manufacturing applications where heat exposure is a constant challenge.

In a comparative analysis, traditional sealants, such as polyurethane or acrylic, may offer a lower initial cost, but their performance can degrade significantly in high-heat environments. Data from the International Sealant Association indicates that businesses using high-temperature silicone sealant have seen a notable increase in product lifespan and reliability, surpassing traditional options by as much as 50% in durability assessments. These sealants maintain their flexibility and adhesion, which is crucial for applications prone to thermal cycling and mechanical stress.

Tips: When selecting a sealant for high-temperature applications, always check the manufacturer’s specifications for temperature limits and compatibility with materials. Additionally, perform a preliminary adhesion test on the substrate to ensure optimal performance. Lastly, consider the cured sealant’s resistance to chemicals and environmental factors to enhance longevity.

High-temperature silicone sealants have become indispensable in various manufacturing processes, showcasing their unique properties that enable them to withstand extreme conditions. In sectors such as automotive and aerospace, these sealants are used for assembling components that experience high thermal fluctuations. Their exceptional thermal stability allows manufacturers to ensure that joints and seams remain intact, preventing leaks and maintaining structural integrity even in demanding environments.

Moreover, in the electronics industry, high-temperature silicone sealants are employed to protect sensitive components from damage caused by heat and moisture. These sealants offer a reliable barrier that enhances the durability and longevity of electronic devices. Their resistance to chemicals and environmental factors further enhances their suitability in industrial applications, allowing manufacturers to enhance product quality and performance while adhering to stringent safety standards. This versatility makes high-temperature silicone sealants a go-to solution for various challenges faced in modern manufacturing.

High-temperature silicone sealant is engineered to withstand extreme environmental conditions, making it an invaluable asset in various industrial applications. Its unique formulation allows it to resist not only high temperatures but also harsh chemicals, UV radiation, and moisture. This combination of durability and resilience ensures that it performs excellently in environments that would typically degrade standard sealants. In thriving industries such as aerospace, automotive, and manufacturing, where equipment is often exposed to extreme heat and corrosive substances, high-temperature silicone sealant acts as a reliable barrier, extending the lifespan of components and improving operational safety.

Moreover, high-temperature silicone sealants are crucial in applications requiring thermal stability, such as in electronic devices and HVAC systems. Their ability to maintain integrity under continuous thermal cycling prevents failures and enhances energy efficiency. The flexibility of silicone also allows for effective sealing in variable joint configurations, further ensuring performance under stress. As industries continue to evolve and operate in more demanding conditions, the role of high-temperature silicone sealants will undoubtedly expand, offering innovative solutions to meet the challenges of modern industrial environments.